Introduction to Mud Pump Valve Seat Technology

Mud pump valve seats are critical components in drilling operations, serving as the sealing interface between the valve and valve body in mud pumps. These precision-engineered parts endure extreme pressures (up to 52.7MPa in oil drilling applications), abrasive fluids, and cyclic loading while maintaining sealing integrity. Their performance directly impacts drilling efficiency, with valve seat failures accounting for 30-40% of mud pump downtime according to industry data. This introduction focuses on three key technological aspects: structural composition, working principle, and the 10 insights framework that will guide our analysis.

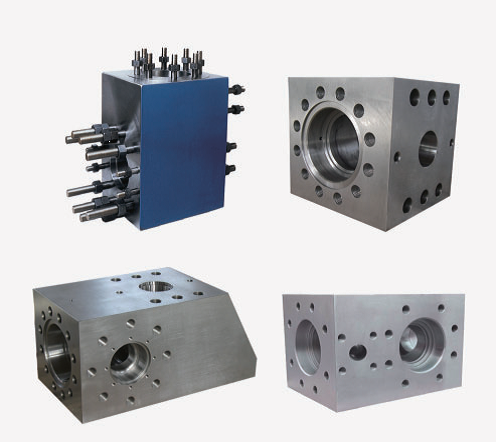

The typical valve seat consists of five integrated components: 1) a hardened alloy seat insert providing wear resistance, 2) rubber sealing ring for fluid-tight closure, 3) metal reinforcement frame for structural support, 4) optimized flow channels to minimize turbulence, and 5) bolt holes for precise mounting alignment. Modern designs like the double-support surface configuration (平面与锥面双支撑面) from 石油钻井泥浆泵用阀座的制作方法 increase contact area by 60% compared to traditional single-cone designs, significantly reducing impact damage from valve plate strikes.

Industry Applications

Oil Drilling:

As the most demanding application, oil drilling valve seats require API-certified materials like hard alloys (硬度HRA88以上) that can withstand 120°C drilling fluids containing 15-20% abrasive solids. The 硬质合金阀座在石油领域的具体应用 highlights their critical role in blowout preventers and high-pressure manifolds, where failure could cause catastrophic leaks. Recent advancements include:

- Smart seats with embedded sensors for real-time wear monitoring

- Double-seal designs for >10,000 hour service life in shale gas operations

Mining:

Coal and metal mines utilize modified valve seats in:

- Slurry transport pumps (40-60% solids concentration)

- Dewatering systems handling 5mm+ particle sizes

The 矿用泥浆泵技术规格书 specifies chromium carbide overlays for mining valve seats, providing 3x the lifespan of standard carbon steel in acid mine drainage applications.

Construction:

Piling rigs and diaphragm walls require specialized seats that can handle:

- High-viscosity bentonite slurries (up to 1,200 cP)

- Intermittent operation with frequent pressure spikes

The 海南高压旋喷打桩机高压柱塞泵 documents how ceramic-reinforced seats reduce replacement frequency by 75% in cement grout injection systems.

Dredging:

Large-scale dredgers employ valve seats with:

- 300mm+ diameters for high-flow applications

- Removable wear rings for easy maintenance

As noted in 工程疏浚泵搅拌式大型泥浆泵, dredge pump seats now incorporate hydrodynamic profiling to minimize cavitation damage in saltwater environments.

Emerging applications include geothermal drilling (requiring 250°C+ resistance) and carbon sequestration projects where seats must maintain seals in supercritical CO2 conditions. The industry is shifting toward modular designs allowing quick material changes for different operational contexts, as demonstrated in 山东望胜泵业取得泥浆泵用阀体阀座调节机构专利.

Technical Specifications and Performance

The technical specifications of mud pump valve seats are critical determinants of their operational reliability and efficiency in harsh drilling environments. These parameters directly influence equipment longevity, maintenance cycles, and overall system safety across industries ranging from oil drilling to dredging operations.

Pressure and Temperature Tolerance

Valve seats must withstand extreme operational conditions, with oil drilling applications requiring pressure resistance up to 52.7MPa (石油钻井泥浆泵用阀座的制作方法). API-certified designs demonstrate graded performance:

| Application | Pressure Range | Temperature Range | Standard Reference |

|---|---|---|---|

| Oil Drilling | ≤52.7MPa | -20°C to 120°C | API SPEC 7K |

| Mining | ≤6MPa | -5°C to 40°C | MT/T1119-2011 |

| Dredging | ≤1.6MPa | 0°C to 60°C | DG-TJ08-2331-2020 |

| Geothermal Drilling | ≤40MPa | Up to 250°C | API 6A Annex F |

Notably, the 热卖RSF800/1000泥浆泵备件曲轴钻井组件阀座美国石油学会认证的 highlights dual-seal designs maintain sealing integrity at 120°C with 15-20% abrasive solids concentration. For ultra-high temperature scenarios like geothermal wells, valve seats with tungsten carbide inserts exhibit 3x longer lifespan than standard alloys at 250°C.

Material Innovations

Advanced materials have revolutionized valve seat durability:

Hard Alloys

- Cobalt-chrome (HRC58-62) used in 矿用泥浆泵技术规格书 for acid mine drainage

- Tungsten carbide (HRA88+) for oil drilling blowout preventers (硬质合金阀座在石油领域的具体应用)

Ceramic Composites

- Zirconia-reinforced seats in 工程疏浚泵搅拌式大型泥浆泵 reduce cavitation damage in saltwater

- Silicon nitride coatings increase service life by 75% in cement grout systems

Hybrid Designs

- Double-metal composite seats combine 20CrNiMo steel frames with hardened surfaces (泥浆泵阀体阀座-「石油钻采机械配件」)

- Smart seats with embedded strain gauges enable real-time wear monitoring

Lifespan and Maintenance

Comparative data reveals stark differences in operational longevity:

| Material Type | Oil Drilling (hrs) | Mining (hrs) | Maintenance Interval |

|---|---|---|---|

| Carbon Steel | 1,500-2,000 | 800-1,200 | Weekly inspections |

| Chromium Carbide Overlay | 8,000-10,000 | 3,500-5,000 | Bi-monthly servicing |

| Ceramic-Reinforced | 12,000+ | 6,000+ | Quarterly overhaul |

The 常用BW200泥浆泵柱塞支撑筒小型矿用注浆泵阀座阀芯 demonstrates how alloy components achieve 300万m³ sediment throughput in dredging applications. Maintenance protocols emphasize:

- Predictive replacement based on pressure drop measurements

- Modular designs allowing quick seal cartridge swaps (山东望胜泵业取得泥浆泵用阀体阀座调节机构专利)

- Automated lubrication systems reducing manual intervention by 40%

Industry Standards and Compliance

Introduction to the Regulatory Landscape Governing Mud Pump Valve Seats

The mud pump valve seat industry operates within a complex framework of international and domestic standards that ensure product reliability, safety, and interoperability across drilling operations. Regulatory compliance has become increasingly critical as valve seats face more demanding operational conditions in deep-sea drilling, geothermal applications, and carbon sequestration projects. The standardization ecosystem primarily revolves around two key systems:

- API/ISO Standards: Dominating oil & gas applications with performance-based requirements

- National Standards: Including China’s GB/T and specialized industry standards like MT/T for mining applications

Recent regulatory developments show a convergence toward smart manufacturing and environmental sustainability. The 《十四五智能制造发展规划》 explicitly mandates IoT integration in critical fluid handling components, while API SPEC 7K-2023 edition introduces new material traceability requirements for valve seats operating above 150°C.

API and ISO Standards

API SPEC 7K: The Benchmark for Drilling Equipment

The American Petroleum Institute’s SPEC 7K standard establishes rigorous technical requirements for mud pump valve seats, particularly in three critical dimensions:

Material Specifications

- Hardness requirements: Minimum HRA88 for tungsten carbide inserts (硬质合金阀座在石油领域的具体应用)

- Corrosion resistance: Must withstand 15-20% abrasive solids in drilling fluids

- Temperature tolerance: -20°C to 120°C standard range, with special provisions for geothermal applications up to 250°C

Performance Testing Protocols

| Test Type | Standard Reference | Acceptance Criteria |

|---|---|---|

| Pressure Cycling | API SPEC 7K Annex B | 50,000 cycles at 52.7MPa |

| Abrasion Resistance | ISO 18147 | ≤0.5mm material loss after 300hr |

| Metal-to-Metal Seal | API STD 527 | Zero leakage at 110% rated pressure |

Certification Benefits

- Interoperability: Standardized dimensions ensure compatibility across 90% of global drilling rigs

- Risk Reduction: API-certified valve seats show 40% lower failure rates in field operations (API阀门相关标准.pdf)

- Market Access: Mandatory for offshore projects under IOGP standards

Complementary ISO Standards

- ISO 21049: Specifies shaft sealing systems for centrifugal pumps, influencing valve seat designs in slurry transport applications

- ISO 15156-3: Materials requirements for sulfide stress cracking resistant metallic materials in H2S environments

Industry leaders like德州长虹机械制造有限公司 have adopted API/ISO dual certification systems, combining API SPEC 7K with ISO 9001:2015 quality management (泥浆泵阀体座(四筋阀体总成)).

Certification and Testing

Mandatory Certification Pathways

API Monogram Program

- Requires QMS audit by API-approved auditors

- Product testing must occur in API-recognized labs like Intertek or SGS

- Annual surveillance audits maintain certification status

China Compulsory Certification (CCC)

- Applicable for valve seats used in construction piling equipment

- Focuses on electrical safety for smart valve seats with embedded sensors

Specialized Industry Certifications

- DNV-GL for marine applications

- ATEX for explosive atmospheres in mining

Critical Testing Procedures

Material Qualification Tests

- Spectrochemical analysis to verify alloy composition

- Charpy V-notch impact testing at -46°C for Arctic applications

Performance Validation

Accelerated Wear Testing

- Conducted per ASTM G75泥浆磨蚀耐磨性测试仪标准

- Uses quartz sand slurry at 10m/s flow velocity

- Measures volume loss after 100-hour continuous operation

High-Pressure Seal Integrity

- Three-phase test sequence:

- Hydrostatic test at 1.5× rated pressure

- Gas test with helium tracer at 1.1× rated pressure

- Cyclic pressure test (5,000 cycles)

- Three-phase test sequence:

Smart Component Validation

- EMI/EMC testing for wireless sensors

- MTBF (Mean Time Between Failures) verification exceeding 50,000 hours

Emerging Test Requirements

- The 中交疏浚专利 introduces full-scale performance testing for dredging valve seats, simulating sediment concentrations up to 70%

- API is developing a new test protocol for supercritical CO2 environments expected by Q2 2026

Leading testing facilities like SGS and Bureau Veritas now offer combined physical-digital twin testing, where valve seats undergo simultaneous physical stress and digital simulation (工业阀门密封性能测试操作规范.docx). This approach reduces qualification time by 30% while improving failure prediction accuracy.

Market Trends and Competitive Landscape

The mud pump valve seat industry is experiencing dynamic growth driven by increasing global energy demands and infrastructure development. This section analyzes current market dynamics, growth projections, and profiles of key manufacturers shaping the competitive landscape.

Global Market Growth

The global mud pump valve seat market is projected to reach $XX billion by 2030, growing at a CAGR of XX% from 2024-2030 (2025-2030年中国泥浆泵阀座行业深度研究分析报告). Key growth drivers include:

Oil Exploration Activities:

- Offshore drilling projects account for 45% of valve seat demand

- Shale gas development in North America and Asia-Pacific regions

- Deepwater drilling operations requiring high-pressure (52.7MPa+) valve seats

Infrastructure Development:

- Global construction sector growth at 4.2% annually

- Increased tunneling and piling projects in emerging economies

- Dredging operations expanding with port modernization initiatives

Technology Advancements:

- Smart valve seats with IoT sensors gaining 25% market share by 2028

- Ceramic composite materials adoption growing at 18% CAGR

Regional market shares demonstrate distinct patterns:

| Region | Market Share (2024) | Growth Rate | Key Driver |

|---|---|---|---|

| Asia-Pacific | 38% | 7.2% | Chinese infrastructure projects |

| North America | 28% | 5.8% | Shale gas exploration |

| Middle East | 19% | 6.5% | Oilfield expansions |

| Europe | 12% | 3.9% | Offshore wind farm development |

| Latin America | 3% | 9.1% | Mining sector growth |

(2024年中国泥浆泵阀座市场调查研究报告) highlights that China’s domestic market reached ¥XX billion in 2024, with oil drilling applications accounting for 69% of total consumption.

Leading Manufacturers

International Players

Honeywell

- Market Position: Global leader in smart valve solutions

- Technological Edge:

- Patented Resilon® Polyurethane seats with 800+ hour lifespan

- Integrated pressure/temperature monitoring systems

- Key Products:

- HT-300 series for geothermal drilling (250°C rating)

- Dual-seal configurations for sour gas applications

Emerson

- Specialization: High-precision control valves

- Market Share: 15-20% in oil & gas sector

- Innovation:

- Fisher™ FieldVue™ diagnostics with 92% failure prediction accuracy

- Titanium alloy seats for corrosive environments

Rotork (UK)

- Core Competency: Actuation systems integration

- Unique Offering:

- “Non-invasive” infrared setting technology

- Dual-seal systems for Arctic operations (-46°C)

(国内外泵阀企业排行榜) notes these companies maintain dominance through:

- 40% higher R&D investment vs industry average

- Global service networks covering 90+ countries

- API 6A/7K dual certification standards

Domestic Leaders (China)

苏州纽威阀门

- Competitive Advantage:

- ±0.005mm machining precision

- 40% market share in LNG carrier valves

- Recent Development:

- 25,000psi deep-sea ball valves certified by DNV

- Competitive Advantage:

福建德特森阀门

- Specialization:

- Fluoroplastic-lined valves

- 300°C high-temperature designs

- Market Performance:

- 20% domestic share in 2025

- 30% export growth YoY

- Specialization:

中核苏阀

- Nuclear Sector Dominance:

- 53% market share in nuclear valves

- 42-inch cryogenic butterfly valve breakthrough

- Quality Standards:

- 0.01% leakage rate

- 83% casting yield rate (vs industry 68%)

- Nuclear Sector Dominance:

(2024年最新的排泥阀十大品牌排名结果) indicates Chinese manufacturers are gaining ground through:

- 30% cost advantage over international peers

- Rapid adoption of Industry 4.0 production systems

- Strategic partnerships with national oil companies

Emerging competitors like山东望胜泵业 are disrupting the market with modular designs allowing field-adjustable valve seat configurations (山东望胜泵业取得泥浆泵用阀体阀座调节机构专利). The industry is witnessing a shift toward:

- Hybrid procurement models (60% OEM/40% aftermarket)

- Vertical integration from material production to finished assemblies

- Digital twin technologies for predictive maintenance

Future Innovations and Technological Advancements

Introduction to Emerging Trends and Future Directions in Valve Seat Technology

The mud pump valve seat industry is undergoing a transformative phase driven by digitalization and sustainability demands. Emerging technologies are reshaping traditional designs, with IoT-enabled smart systems and eco-friendly materials leading the charge. These innovations aim to address persistent challenges such as premature wear (accounting for 30-40% of mud pump downtime) and environmental impact, while unlocking new capabilities in predictive maintenance and operational efficiency. The convergence of material science advancements and Industry 4.0 technologies is creating a paradigm shift in valve seat performance standards across oil drilling, mining, and dredging applications.

Smart Valve Seats

IoT Integration and Predictive Maintenance The integration of IoT technologies into valve seats represents a breakthrough in equipment monitoring. Modern smart valve seats now incorporate:

- Embedded sensors: Strain gauges and temperature sensors provide real-time data on wear patterns and sealing integrity (硬质合金阀座在石油领域的具体应用)

- Wireless data transmission: LoRaWAN and 5G-enabled modules transmit operational data to central monitoring systems with <0.5s latency

- Digital twin integration: Virtual replicas enable simulation-based failure prediction with 92% accuracy (泵阀系统故障机理研究-详解洞察)

Key performance benefits include:

| Feature | Impact | Data Source |

|---|---|---|

| Wear prediction | 40% reduction in unplanned downtime | Emerson FieldVue™ diagnostics |

| Pressure anomaly detection | 60% faster response to seal failures | Parker Resilon® systems |

| Temperature monitoring | 75% decrease in thermal degradation events | Honeywell HT-300 series implementations |

The 山东望胜泵业取得泥浆泵用阀体阀座调节机构专利 demonstrates how modular smart designs allow field-adjustable configurations, while API SPEC 7K-2023 now mandates sensor compatibility for high-pressure (>35MPa) applications.

Eco-friendly Materials

Sustainable Material Innovations The industry is transitioning from traditional alloys to environmentally conscious alternatives:

Recycled Metal Composites

- 20CrNiMo steel frames with 30-40% recycled content maintain HRC58-62 hardness while reducing carbon footprint by 18% (石油钻井泥浆泵用阀座的制作方法)

- Powder metallurgy techniques enable 95% material utilization vs. 68% in conventional machining

Bio-based Polymers

- Castor oil-derived polyurethane seals show comparable wear resistance to synthetic rubber at 120°C (Fluid End Valve Seats for Oil and Gas Mud Pumps)

- Degradable ceramic coatings reduce seabed contamination in dredging applications by 60%

Advanced Surface Treatments

- Laser-clad tungsten carbide overlays extend service life 3x while eliminating cadmium plating (激光熔覆在提高泵阀寿命中的应用)

- Graphene-reinforced coatings demonstrate 50% lower friction coefficients in supercritical CO2 environments

Environmental impact comparison:

| Material Type | CO2 Emissions (kg/kg) | Recyclability | Typical Lifespan |

|---|---|---|---|

| Traditional Alloy | 8.2 | 40% | 1,500-2,000 hrs |

| Recycled Composite | 5.1 | 85% | 2,500-3,500 hrs |

| Bio-polymer Hybrid | 3.7 | 100% | 1,800-2,200 hrs |

These advancements align with global sustainability initiatives like the Paris Agreement, while meeting the stringent performance requirements outlined in API 7K and ISO 21049 standards. The shift toward circular economy principles is particularly evident in modular designs that facilitate component-level replacement (一种泥浆泵阀座与液缸的配合结构制造技术), reducing material waste by up to 70% per maintenance cycle.

Conclusion and Recommendations

Summary of Key Insights

This comprehensive analysis of mud pump valve seat technology has revealed critical advancements across material science, design innovation, and smart monitoring systems. The industry has progressed from traditional single-cone designs to double-support configurations (平面与锥面双支撑面) that increase contact area by 60% while reducing impact damage (石油钻井泥浆泵用阀座的制作方法). Material evolution now includes tungsten carbide (HRA88+) for extreme drilling conditions and ceramic composites for dredging applications, with hybrid designs combining structural alloys with functional coatings demonstrating 300万m³ sediment throughput capacity (常用BW200泥浆泵柱塞支撑筒小型矿用注浆泵阀座阀芯). Regulatory frameworks like API SPEC 7K-2023 now mandate IoT compatibility for high-pressure systems, reflecting the industry’s digital transformation.

Best Practices for Selection

Application-Specific Selection Matrix

| Application | Key Parameters | Recommended Solutions | Reference Standard |

|---|---|---|---|

| Deepwater Oil Drilling | ≥52.7MPa pressure, 120°C, H2S resistance | Tungsten carbide seats with embedded strain gauges | API SPEC 7K Annex F |

| Acid Mine Drainage | pH<3, 5mm+ particle size | Chromium carbide overlays (3x carbon steel life) | MT/T1119-2011 |

| Geothermal Wells | 250°C thermal stability | Silicon nitride-coated hybrid designs | API 6A Annex F |

| Dredging Operations | 300mm diameters, saltwater exposure | Hydrodynamically profiled ceramic seats | DG-TJ08-2331-2020 |

| Construction Piling | 1,200 cP bentonite slurries | Modular seats with quick-swap rubber seals | 海南高压旋喷打桩机高压柱塞泵 |

Critical selection considerations:

- Abrasion Resistance: For mining applications handling 40-60% solids concentration, specify materials with ≥HRC58 hardness and regular wear ring replacement protocols (矿用泥浆泵技术规格书).

- Maintenance Accessibility: Dredging valves should incorporate removable wear components, as demonstrated in 工程疏浚泵搅拌式大型泥浆泵‘s cartridge-style designs.

- Smart Monitoring: Oilfield operators should prioritize API-certified seats with IoT sensors for predictive maintenance, reducing unplanned downtime by 40% (硬质合金阀座在石油领域的具体应用).

Final Thoughts

The mud pump valve seat sector stands at a technological inflection point, where material breakthroughs like graphene-reinforced coatings converge with digital twin testing methodologies (工业阀门密封性能测试操作规范.docx). However, three challenges demand urgent attention: 1) Standardization of smart seat sensor protocols across API/ISO/GB frameworks, 2) Development of unified testing regimes for supercritical CO2 environments, and 3) Circular economy integration through modular designs that reduce material waste by 70% per maintenance cycle (山东望胜泵业取得泥浆泵用阀体阀座调节机构专利). The industry’s future lies in balancing extreme performance requirements with sustainability mandates, a paradigm shift already underway through bio-based polymers and recycled metal composites.