MUP PUMP PARTS

China Longchao Petroleum Machinery Forging Co., Ltd.

Mud pumps are critical equipment in oil drilling operations, primarily used to pump drilling fluid (mud) from the surface to the bottom of the well, performing important functions such as cooling the drill bit, carrying cuttings, and stabilizing the wellbore. To ensure long-term stable operation in high-pressure, high-wear environments, mud pumps are composed of multiple precision components, typically divided into two major components: the fluid end and the power end.

MUP PUMP PARTS

38 Years Of Undefeated Success

We are committed to precision, performance, and long-term value. Our products meet the highest quality standards in the industry.

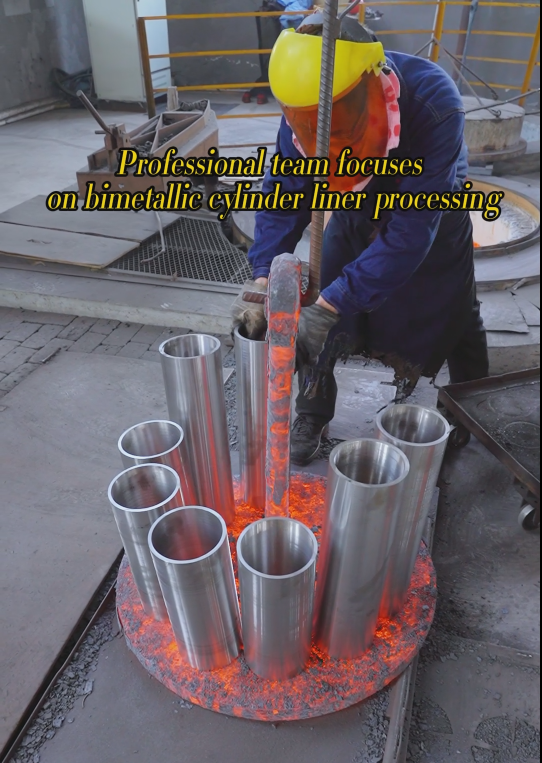

Founded in 1980, LONGCHAO has grown into China’s leading mud pump liner manufacturer with over one million units delivered globally. Our liners are compatible with major OEM brands and are trusted by top drilling contractors across North America, the Middle East, and Europe. Every product is engineered in-house to ensure unmatched durability and reliability in demanding oilfield environments.

32745㎡

Factory area

30+

Years of experience with proud

520+

24-hour after-sales service staff

1520+

production staff

Mud Pump Parts

About Us

Founded in 1980, LONGCHAO has grown into China’s leading mud pump liner manufacturer with over one million units delivered globally. Our liners are compatible with major OEM brands and are trusted by top drilling contractors across North America, the Middle East, and Europe. Every product is engineered in-house to ensure unmatched durability and reliability in demanding oilfield environments.

LC MUD PUMP PARTS

Superior Craftsmanship

Mud pumps are critical equipment in oil drilling operations, primarily used to pump drilling fluid (mud) from the surface to the bottom of the well, performing important functions such as cooling the drill bit, carrying cuttings, and stabilizing the wellbore. To ensure long-term stable operation in high-pressure, high-wear environments, mud pumps are composed of multiple precision components, typically divided into two major components: the fluid end and the power end.

We Follow Best Practices

“Details determine success or failure, and quality creates the future”

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs

Mud Pump Parts

Mud Pump Liners

- High temperature resistance

- High pressure resistance

- Corrosion and Erosion Resistance

- API 7K

- Reduced maintenance costs

- Reduced downtime losses

Mud Pump Parts

Mud Pump Valves

- Ultra-Wear-Resistant Structure

- Zero-Leakage Dynamic Seal

- Quick-Disassembly Modularity

- API 7K

- Real-Time Wear Monitoring

- Intelligent Error Prevention

Mud Pump Parts

Mud Pump Pistons

- Ultra-High Wear Resistance

- Sealing and Leakage Prevention

- Quick-Change Modularity

- API 7K

- Intelligent Lifetime Warning

- ISO 9001

Mud Pump Parts

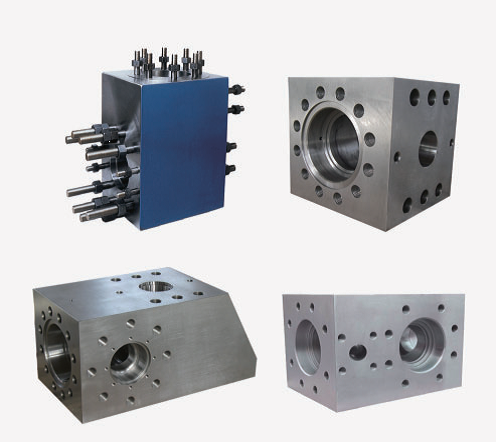

Mud Pump Fluid Ends

- Multi-layer composite fatigue resistance

- Self-compensating high-pressure seal

- Corrosion and Wear Protection

- API 7K

- Intelligent Detection

- No Disassembly

Our production plants

We are committed to precision, performance, and long-term value. Our products meet the highest quality standards in the industry.

Frequently Asked Questions

MUD PUMP PARTS FAQ

Mud Pump Parts

Mud pump parts are the components that constitute a mud pump, a critical piece of drilling equipment used to circulate drilling fluid (mud) in oil and gas operations. Common parts include cylinder liners, pistons, valves (ball/ gate), valve seats, guide sleeves, seals, ceramic liners, and pump heads. These parts work together to maintain the pump’s efficiency, pressure, and durability.

The main components of a mud pump include:

– Cylinder Liner: A cylindrical sleeve that houses the piston and withstands high-pressure mud flow.

– Piston: Reciprocates inside the liner to create suction and discharge pressure.

– Valve Assembly: Controls mud flow (inlet/ outlet) with parts like ball valves and valve seats.

– Guide Sleeve: Guides the piston rod to prevent misalignment.

– Seals: Prevents mud leakage and protects internal components (e.g., O-rings, packing).

– Pump Head: Connects the liner and valve assembly, directing mud flow.

The key differences lie in the number of cylinders/pistons and structural design:

– Triplex: 3 cylinders/pistons, designed for high-pressure applications (e.g., deep drilling). Parts include 3 liners, 3 pistons, and corresponding valves.

– Quintuplex: 5 cylinders/pistons, offering smoother operation and higher efficiency. Parts are more numerous (e.g., 5 pistons, 5 valves) than triplex pumps.

– Duplex: 2 cylinders/pistons, suitable for lower-pressure operations. Parts include 2 liners, 2 pistons, and simpler valve assemblies (e.g., binocular floating seals).

When selecting mud pump parts, consider:

– Pump Type: Triplex/ quintuplex/ duplex (determines part quantity and compatibility).

– Working Pressure: Higher pressure requires durable materials (e.g., ceramic liners).

– Mud Properties: Viscosity, corrosiveness, and solid content (affects material selection for wear/ corrosion resistance).

– Material: Choose high-strength steel, ceramic, or alloy for longevity.

– OEM Specifications: Ensure parts meet the original manufacturer’s standards for compatibility.

Material directly impacts part performance and lifespan:

– Wear Resistance: Ceramic (e.g., ceramic liners) or hardened steel resists abrasion from solid particles in mud.

– Corrosion Resistance: Alloys (e.g., stainless steel) protect against corrosive mud components (e.g., chemicals).

– Pressure Resistance: Forged steel withstands the high pressure of drilling operations (up to 10,000+ PSI).

– Durability: Quality materials reduce replacement frequency and maintenance costs.

Mud Pump Parts

To extend part life, follow these tips:

– Regular Inspection: Check for wear, cracks, or leakage in liners, pistons, and seals.

– Cleaning: Remove solid particles from the pump head and valve assembly to prevent abrasion.

– Lubrication: Lubricate piston rods and guide sleeves to reduce friction.

– Seal Replacement: Replace worn seals promptly to prevent mud leakage.

– Pressure Monitoring: Avoid exceeding the pump’s maximum pressure to prevent part damage.

Common faults include:

– Cylinder Liner Wear: Caused by abrasive mud, leading to reduced pressure.

– Piston Seal Damage: Leaks due to worn seals, resulting in inefficient mud circulation.

– Valve Leakage: Dirt or wear on valve seats causes reverse mud flow.

– Guide Sleeve Misalignment: Misalignment leads to piston rod wear and reduced efficiency.

– Seal Leakage: Damaged seals allow mud to escape, contaminating internal components.

Signs that parts need replacement:

– Reduced Performance: Decreased mud displacement (flow rate) or pressure.

– Leakage: Visible mud leakage from the pump head or seals.

– Abnormal Noise: Knocking/ grinding sounds indicating misalignment or worn parts.

– Wear Indicators: Liners or pistons exceeding the manufacturer’s wear limits (e.g., liner thickness < minimum specification).

– Frequent Breakdowns: Repeated faults in the same part (e.g., valve leakage) suggest replacement.

OEM Parts: Produced by the pump’s original manufacturer (e.g., Saigao, Caterpillar). They ensure perfect compatibility and meet strict quality standards but are more expensive.

– Aftermarket Parts: Produced by third-party suppliers. They are cheaper but vary in quality. Some are designed for multiple pump brands, but reliability may be inconsistent.

Reliable mud pump parts can be purchased from:

– OEM Suppliers: Directly from the pump manufacturer (e.g., Saigao, as mentioned in search results).

– Authorized Distributors: Resellers approved by the manufacturer, ensuring genuine parts.

– Online Marketplaces: Platforms like Alibaba (verified suppliers offer parts like ceramic liners, cylinder liners).

– Industry Trade Shows: Events like OTC (Offshore Technology Conference) where manufacturers showcase products.

We are here to answer your questions and support your needs.