Product Center

MUD PUMP PARTS

Felis etiam pellentesque scelerisque eleifend in aliquam sed morbi nisl lectus mi proin ultricies quis bibendum.

EMAIL Us Today:

josean.lu@lcpumpliner.com

Mud Pump Parts Analysis Diagram

MUD PUMP PARTS

Vulputate vulputate eget cursus nam ultricies mauris, malesuada elementum lacus arcu, sit dolor ipsum, ac felis, egestas vel tortor eget aenean nam nulla est.

Replaceable Rubber piston

Preassure rate: 5,000 psiTemperature rate: 200FSuitable for: Water/Synthetic based mud

Rubber bonded piston

Preassure rate: 5,000 psi;Temperature rate: 200F;Suitable for: Water/Synthetic based mud

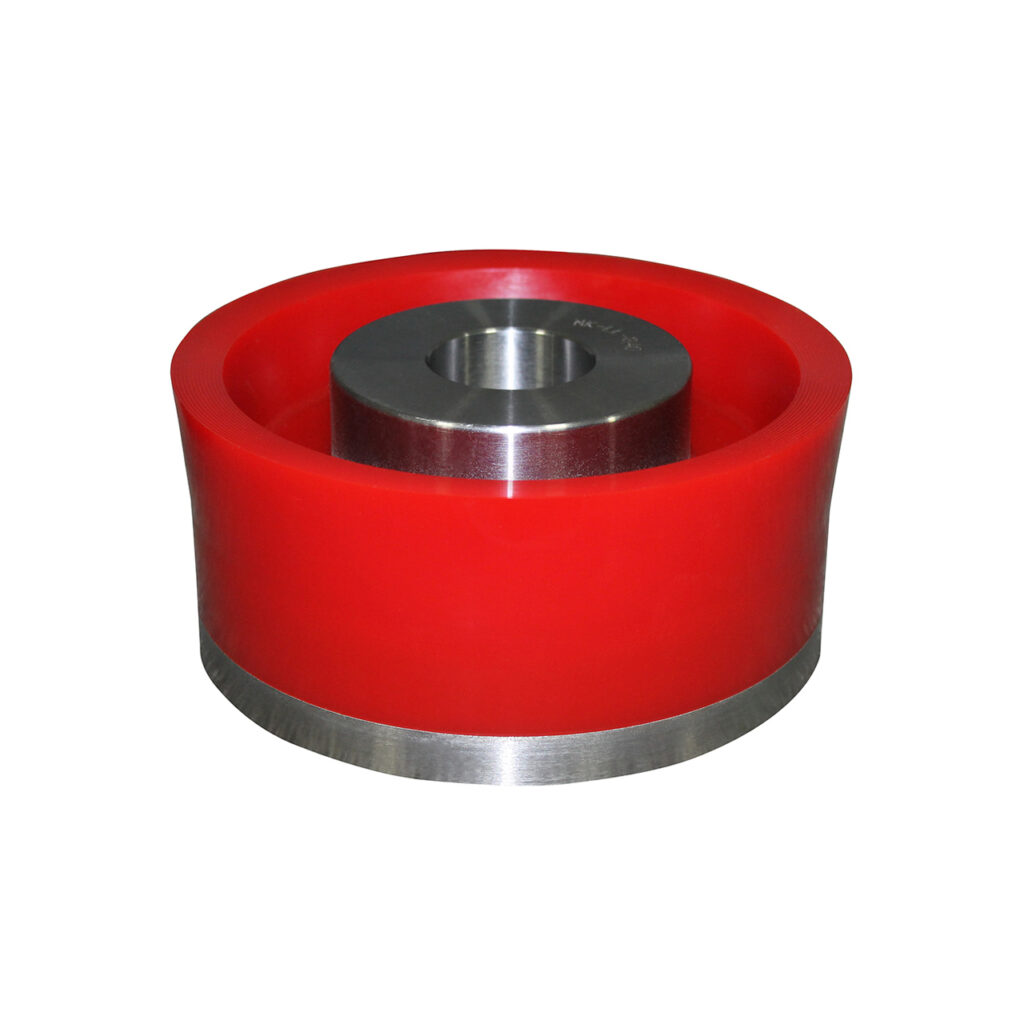

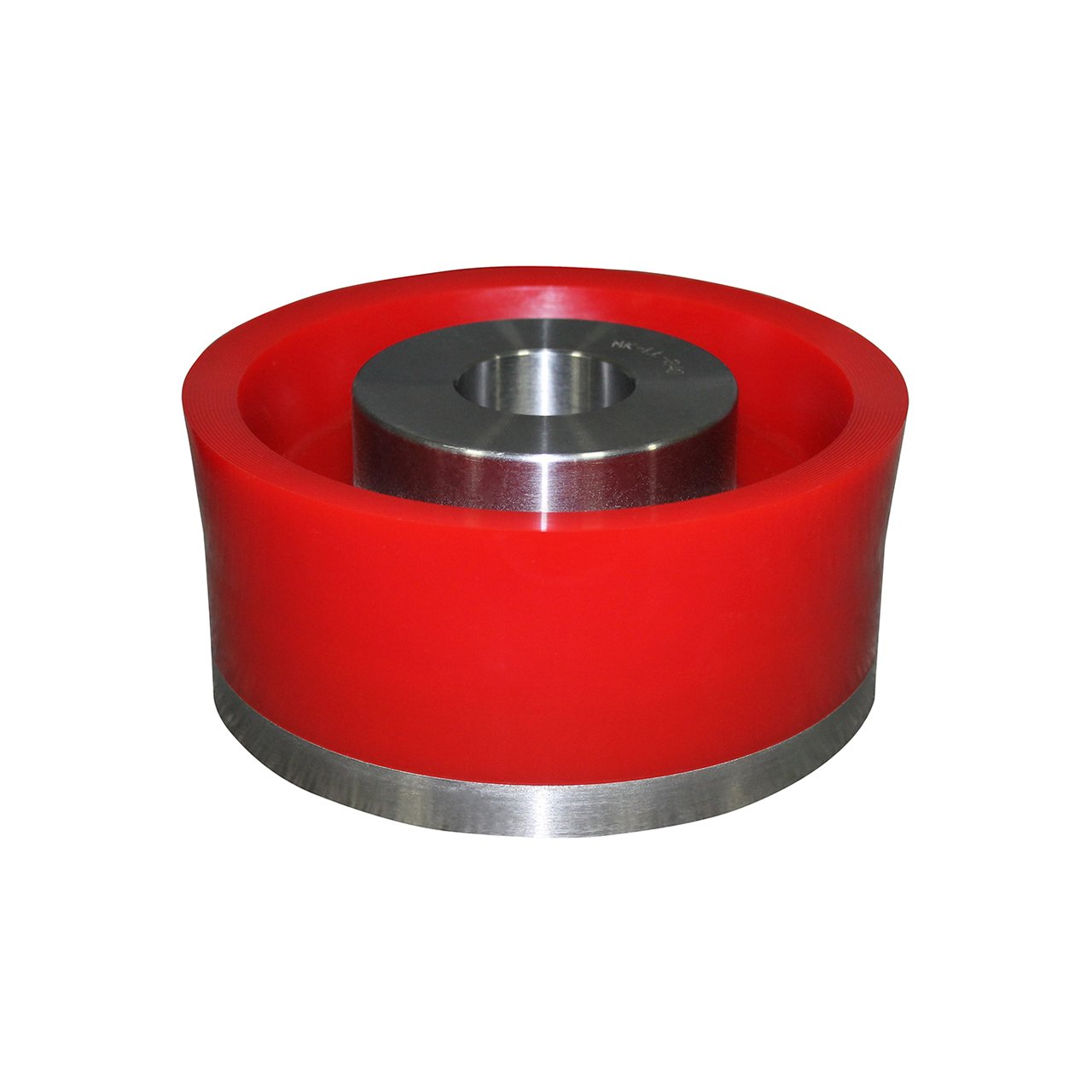

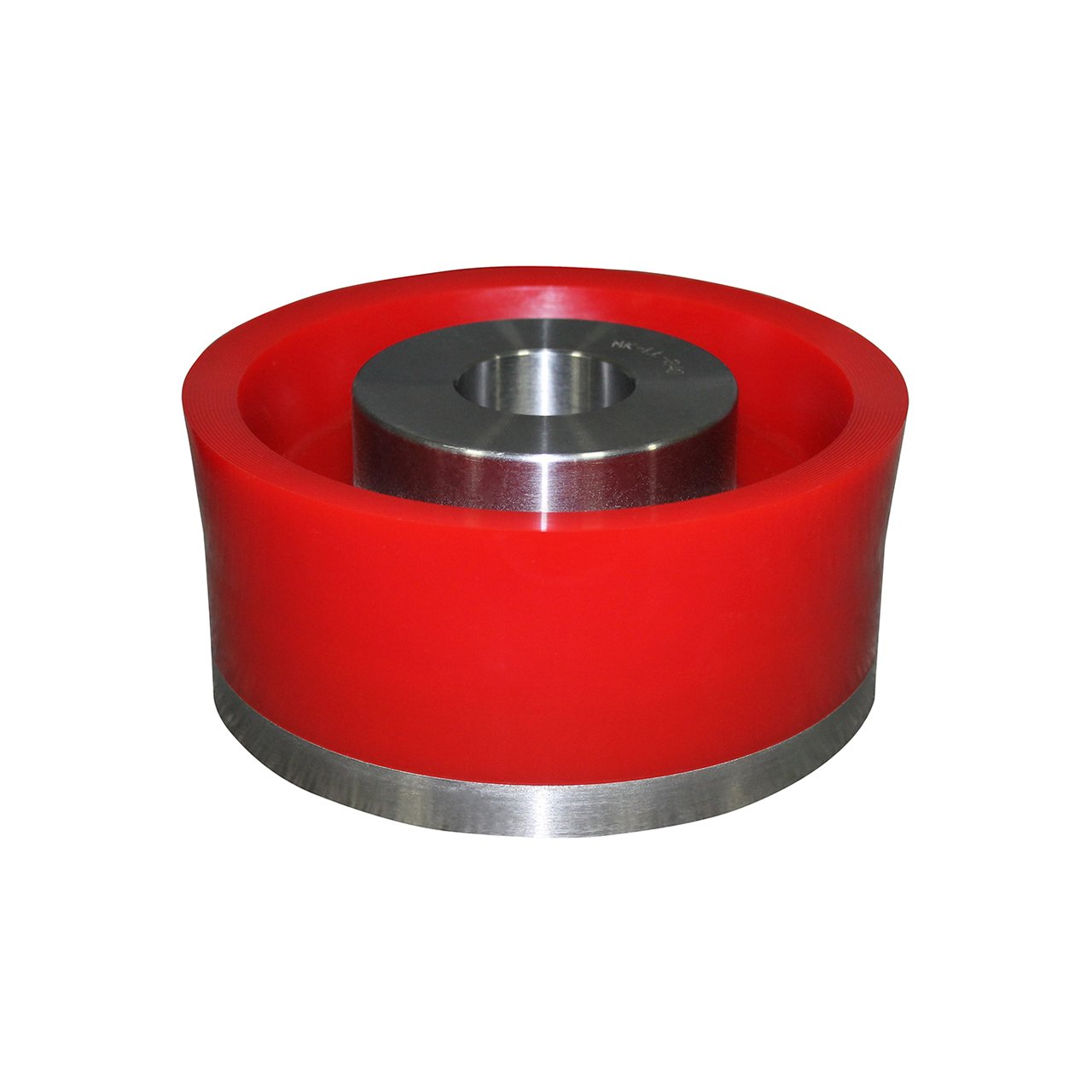

Urethane bond piston

Preassure rate: 5,000 psi;Temperature rate: 180F;Suitable for: Oil/Water based mud

High temperature urethane bonded piston

Preassure rate: 7,500 psi;Temperature rate: 350F;Suitable for:: Oil, Synthetic and Water Muds

Bull nose extreme piston

Preassure rate: 7,500 psi;Temperature rate: 350F; Suitable for: All based muds

Supporting Subheading

Feature One

Material compatibility and customization

Feature Two

Modular structural design

Feature Three

Dynamic optimization of sealing performance

Feature Four

Enhanced wear and fatigue resistance

Feature Five

Adaptability to high-temperature conditions

Feature Six

Dimensional standardization and interchangeability

Supporting Subheading

Feature One

Material compositeness and interface strengthening

Feature Two

Dynamic sealing stability

Feature Three

Tear resistance and fatigue life

Feature Four

Self-lubrication and low friction properties

Feature Five

Corrosion resistance and environmental adaptability

Feature Six

Standardized and modular design

Supporting Subheading

Feature One

High-strength metal-polyurethane composite structure

Feature Two

Dual hardness gradient design

Feature Three

Ultra-low friction and self-lubricating properties

Feature Four

Chemical corrosion resistance and high-temperature stability

Feature Five

Optimized dynamic seal design

Feature Six

Modular maintenance and standardized interchangeability

Supporting Subheading

Feature One

High-temperature resistant composite structure reinforcement;

Feature Two

Gradient hardness design for thermal deformation resistance

Feature Three

Optimized high-temperature dynamic seals

Feature Four

Heat stability and enhanced wear resistance

Feature Five

Chemical corrosion and aging resistance

Feature Six

Modular maintenance and high-pressure adaptability

Supporting Subheading

Feature One

Reinforced materials for extreme working conditions

Feature Two

High-temperature stability design

Feature Three

Dynamic seal optimization technology

Feature Four

Chemical resistance

Feature Five

Fatigue resistance and long life

Feature Six

Modular quick-change

Frequently Asked Questions

Suitable Subtitle

Mud pump pistons are critical components in drilling operations, designed to reciprocate within the pump cylinder to create pressure fluctuations that move drilling fluid (mud) through the system. This ensures efficient hole cleaning, cooling of the drill bit, and removal of cuttings

- Single-Action Pistons: Pump fluid in one direction per stroke (e.g., Triplex Pump Pistons).

- Double-Action Pistons: Pump fluid in both directions (e.g., Duplex Pump Pistons).

- Fail-Safe Pistons: Designed for emergency shutdown scenarios to prevent fluid backflow

- Metallic: High-strength steel or alloy steel for durability in abrasive environments.

- Polyurethane (PU): Used for lightweight, corrosion-resistant applications.

- Composite: Hybrid materials combining rubber/metal for shock absorption and wear resistance [2].

Key factors include:

- Pump Model Compatibility (e.g., Triplex Pump Piston for 6P-HD models).

- Operating Conditions: Pressure ratings, fluid viscosity, and abrasiveness.

- Material Requirements: Choose PU for corrosive fluids or steel for high-pressure environments [2].

Regular inspections are critical:

- Daily: Check for wear, cracks, or misalignment.

- Weekly: Lubricate moving parts and clean debris.

- Monthly: Replace worn seals or piston rods to prevent system failure [4].

Suitable Subtitle

- Reduced Pump Efficiency: Lower pressure/output despite normal RPM.

- Excessive Vibration: Indicates piston rod misalignment or wear.

- Fluid Leaks: Damaged seals or cracks in the piston body [6].

- Proper Lubrication: Use manufacturer-recommended grease for piston rods.

- Avoid Overloading: Operate within the pump’s rated pressure limits.

- Regular Cleaning: Remove abrasive particles from the cylinder to prevent premature wear [4].

While some universal designs exist, compatibility depends on specifications like thread type, diameter, and stroke length. Always verify dimensions against the manufacturer’s guidelines [2].

Extreme heat can:

- Degradate Rubber Seals: Leading to leaks and reduced efficiency.

- Cause Thermal Expansion: Misalignment or seizing if materials expand unevenly.

Use high-temperature-rated materials (e.g., heat-treated steel) in such conditions [7].

- Shut Down the Pump: Ensure the system is depressurized before maintenance.

- Use Proper Tools: Avoid damaging threads or seals during installation.

- Wear PPE: Protect against fluid splashes and sharp edges [6].

We are here to answer your questions and support your needs.