Mud Pump 3-Web Valve & Seat

Discover the power of our valve assemblies engineered to conquer the toughest drilling environments. Redefining efficiency and endurance.

Designed to withstand extreme pressures and abrasive conditions, our high-performance valve assemblies

ensure consistent, reliable operation, day in and day out. Whether you’re tackling deep wells or demanding

terrains, trust American Mud Pumps to keep your mud pumps running stronger and longer.

Suitable Subtitle

- 1. Enhanced Structural Stability with 3-Web Guided Design

- 2. Replaceable Snap-In Insert for Cost Efficiency

- 3. High-Performance Materials for Durability

- 4. API Compliance and Versatility

Suitable Subtitle

- Preassure rate: 7500 psi (seat)

- Temperature rate: 160°F (Std Insert)

- Bore Hardness: Water and synthetic- based

- API sizes: 6-1/4" to 7-1/2"

Feature

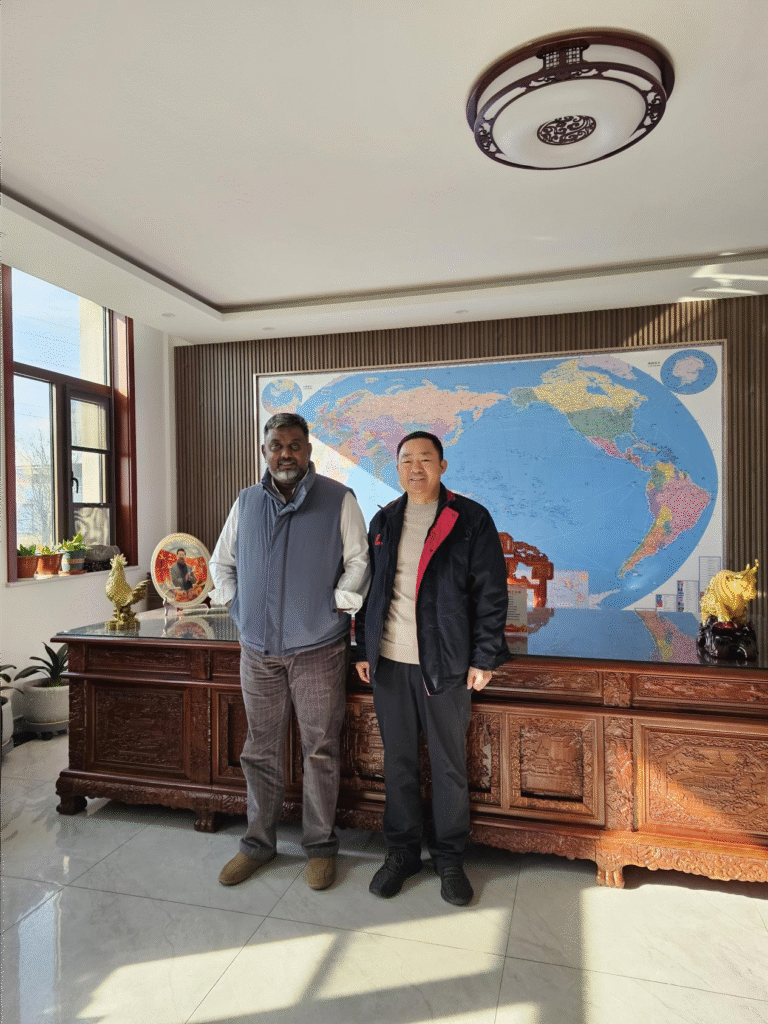

The Mud Pump 3-Web Valve & Seat is a critical component for triplex mud pumps used in oil and gas drilling operations. It features a 3-web center-guided structure designed to enhance stability and durability under high-pressure conditions. The product is part of a full range of mud pump valves and seats, including 4-web valves and full-open valves, and is compatible with various mud pump models. It is manufactured by Beijing Ocean Renda Petroleum Equipment Co., Ltd., a company with over 10 years of experience in petroleum equipment, holding API certification for quality assurance.

2. Key Features

- Structural Design: 3-web center-guided valve for improved alignment and reduced vibration during operation.

- Material Options: Available with urethane inserts or rubber inserts to suit different drilling fluid conditions.

- Certification: Complies with API standards, ensuring reliability and safety in oilfield applications.

- Compatibility: Suitable for multiple mud pump models, including OILWELL series (e.g., A-560-PT, A-350/600-PT, A-850/1100/1400/1700-PT) and others like 3NB series.

3. Technical Specifications

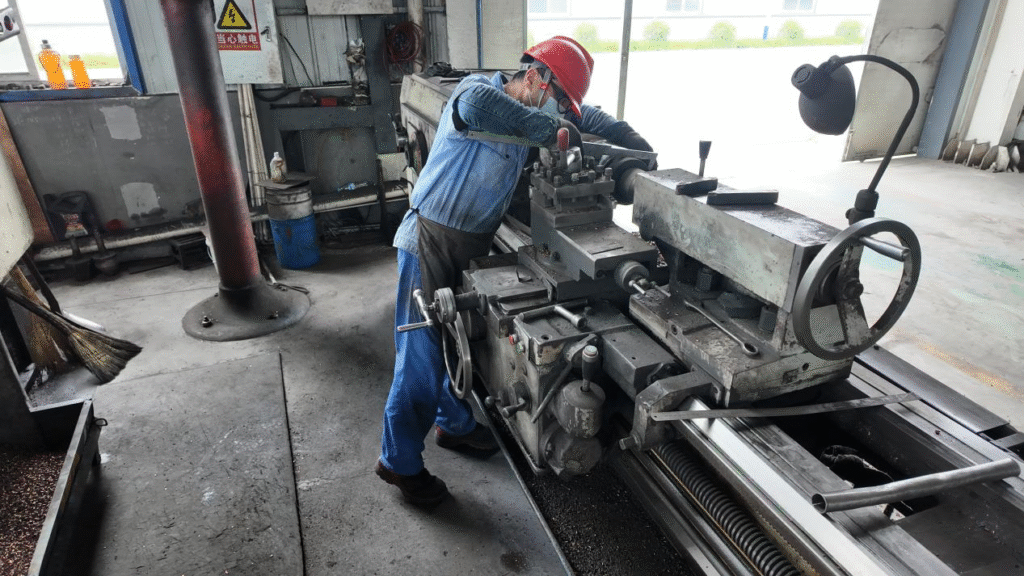

Parameter Details Model Series MTP-3WEB (valve with urethane insert); specific part numbers may vary. Valve Insert Type Urethane or rubber (e.g., MT-U5B-EH, MT-U5C-EEF for related valve models). Seat Compatibility Paired with valve seats such as MT-6ADD-B6. Spring Component Uses valve springs like MT-5710-115. Processing Type Forged carbon steel construction for high strength and wear resistance. 4. Application & Usage

The 3-Web Valve & Seat is primarily used in well drilling operations to control the flow of drilling mud in triplex expansion mud pumps. Its robust design and material selection make it suitable for handling abrasive fluids and high-pressure environments typical in oil and gas exploration

Mud Pump 3-Web Valve & Seat Model Icons

| Model Series | Pressure Rating | Compatible Pumps | Material Grade |

|---|---|---|---|

3W-500 | 5,000 PSI | F-500, F-800 | 20CrMnTi Alloy |

3W-1000 | 7,500 PSI | F-1000, F-1300 | Forged Steel |

3W-1600 | 10,000 PSI | F-1600, F-2200 | AISI 4140 HT |

3W-HP (High-Perf) | 15,000 PSI | Ultra-HP Triplex Pumps | Tungsten Carbide |

Key Specifications

- Design Standard

All models comply with API 7K/ISO 13533 for drilling equipment 2. - Interchangeability

Snap-in inserts allow quick replacement without disassembling the valve body. - Temperature Range

Operates at -30°C to 150°C under abrasive mud conditions.

Mud Pump 3-Web Valve & Seat

What is a 3-Web Mud Pump Valve?

The 3-Web Mud Pump Valve is a center-guided valve system designed for high-pressure mud pumping applications, commonly used in oil & gas drilling, mining, and construction. It features a 3-web structure for stability and includes a replaceable snap-in insert, available in standard and high-temperature versions. The valve body is often oxide-coated to resist corrosion during storage, ensuring durability in harsh environments

What materials are used in 3-Web Valves & Seats?

3-Web Valves and Seats are constructed from high-performance materials to withstand extreme conditions:

- Valve Body: Forged steel or 20CrMnTi alloy (known for high strength and abrasion resistance).

- Seat: Stainless steel (API standard) for pressure resistance.

- Insert: Bonded urethane (available in standard/high-temperature options) for flexibility and long run life.

- Stem: Stainless steel to prevent corrosion and ensure smooth operation

What are the key advantages of 3-Web Valves?

- Enhanced Stability: The 3-web center-guided design reduces vibration and ensures precise alignment under high pressure (5,000–7,500 psi / 34.5–51.7 MPa).

- Longevity: Urethane inserts and forged steel construction provide excellent abrasion resistance, extending service life in high-solids environments.

- Easy Maintenance: Replaceable snap-in inserts simplify repairs, reducing downtime.

- Corrosion Resistance: Oxide coating protects against rust during storage

What applications are 3-Web Valves suitable for?

These valves are ideal for hostile drilling conditions, including:

- Oil & gas drilling (mud circulation systems).

- Mining and construction (slurry pumping).

- High-pressure/high-temperature (HPHT) operations.

- Environments with high solids content (e.g., abrasive muds).

They comply with API standards, making them compatible with most triplex mud pumps (e.g., OILWELL A-850/1100 series)

How to select the right 3-Web Valve for my pump?

Consider these factors:

- Pressure/Temperature Rating: Choose high-temperature inserts for HPHT applications.

- Pump Model: Match valve specifications to your pump (e.g., API seat compatibility).

- Fluid Type: Select urethane inserts based on mud chemistry (standard vs. high-temperature).

- Certifications: Ensure compliance with API and industry standards for safety and performance

We are here to answer your questions and support your needs.