Mud Pump 4-Web Valve & Sea High temperature

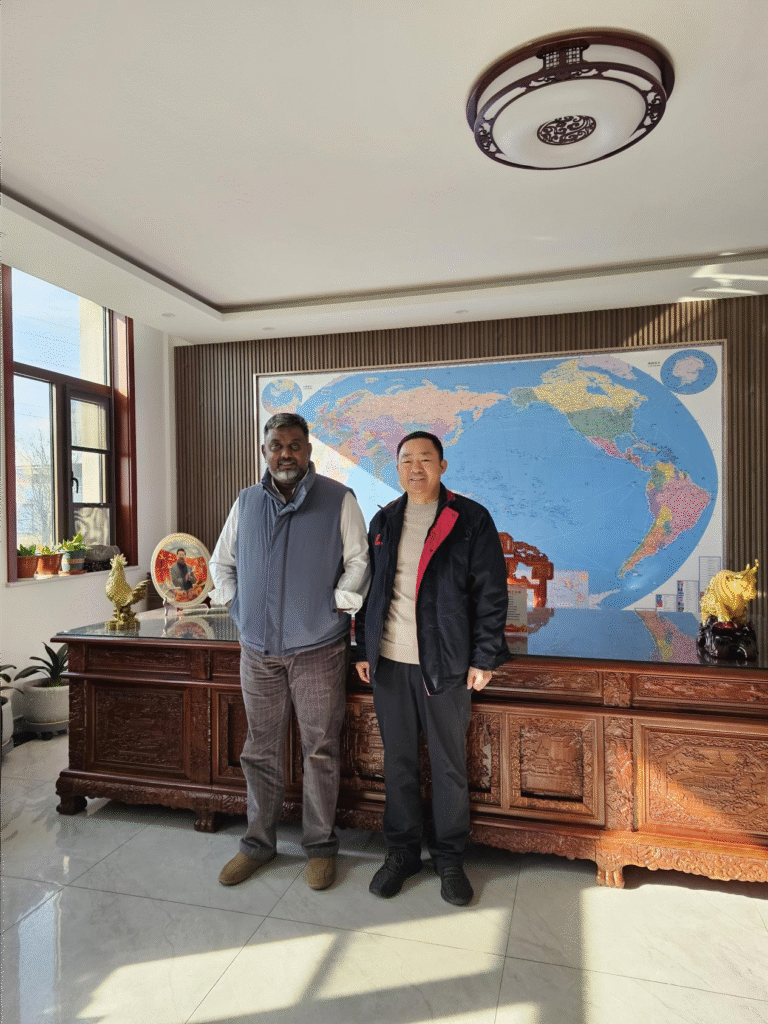

Discover the power of RedRock, the premier choice for valve assemblies engineered to conquer the toughest drilling environments. Redefining efficiency and endurance, RedRock sets a new industry standard with cuttingedge materials and precision craftsmanship that maximize performance while minimizing downtime.

Designed to withstand extreme pressures and abrasive conditions, our high-performance valve assemblies

ensure consistent, reliable operation, day in and day out. Whether you’re tackling deep wells or demanding

terrains, trust RedRock to keep your mud pumps running stronger and longer.

Selling Points

- Enhanced Stability and Durability

- Improved Flow Efficiency

- Robust Construction for Harsh Environments

- Easy Maintenance and Replacement

Basic parameters

- Preassure rate: 7500 psi (seat)

- Temperature rate: 350°F

- Bore Hardness: Water and synthetic- based

- API sizes: 6-1/4 to 7-1/2

Feature

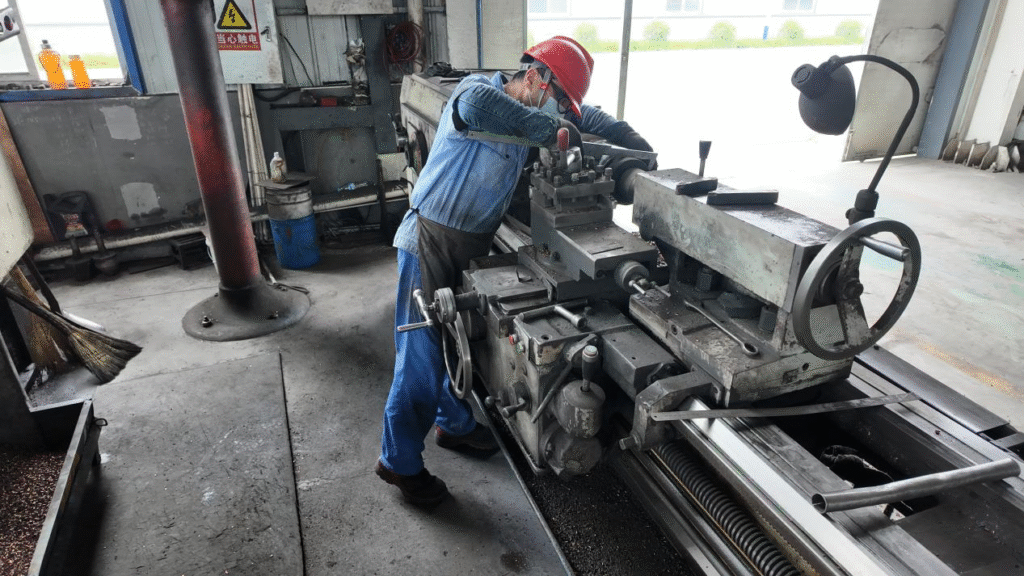

The 4-Web Valve & Seat is engineered for extreme drilling environments, featuring a bonded urethane construction and center-guided design. It excels in high-pressure, high-temperature (HPHT) applications with superior abrasion resistance and extended service life.

Key Specifications & Parameters

Parameter Specification Valve Type 4-Web Center-Guided Valve System Design Double-angle valve with replaceable snap-in insert Material Composition Valve Body: Forged steel (oxide-coated)

Seat/Insert: Bonded urethane (HT variant)Temperature Tolerance High-Temp Version: Up to 200°C (392°F) Pressure Rating 5,000–7,500 psi (34.5–51.7 MPa) Corrosion Resistance Oxide-coated body to prevent storage corrosion Certifications ISO 9001:2015, GB/T 19001-2016 Material Highlights

Bonded Urethane Construction

- Withstands abrasive slurries, high solids, and hostile chemical environments.

- Exceptional wear resistance for extended run life.

High-Temperature Alloy

- Valve Seat/Stem: 20CrMnTi alloy steel (forged) for thermal stability.

- Body: Forged steel with anti-corrosion oxide coating.

Performance Advantages

- Superior HPHT Resilience

- Maintains integrity under pressures ≤7,500 psi and temperatures ≤200°C.

- Optimized Flow Design

- Double-angle geometry reduces turbulence, minimizing erosion risk.

- Modular Maintenance

- Snap-in inserts enable quick replacement without full valve disassembly.

- Abrasion Resistance

- Ideal for drilling fluids with high sand/solid content.

Applications

- Deep-well drilling (oil/gas)

- Geothermal drilling operations

- High-solids mining slurry pumping

Mud Pump 4-Web Valve & Seat High-Temperature Models

| Model | Structure Type | Temperature Range | Pressure Rating | Material | Key Features |

|---|---|---|---|---|---|

| F-1600 Heavy Duty | Bonded Urethane 4-Web | High Temperature | 5,000–7,500 psi (34.5–51.7 MPa) | Forged steel body, Urethane seals | Withstands hostile drilling environments; Superior abrasion resistance 1 |

| FB-1600 Full-Open | Single-piece solid body | High Temperature | ≥7,500 psi (51.7 MPa) | Forged steel | Unrestricted flow; Ideal for high-pressure/high-solids drilling 1 |

| Double Angle Valve | 3-Web/4-Web hybrid design | High Temperature | API Standard | Oxide-coated steel | Replaceable snap-in insert; Corrosion-resistant storage coating 1 |

Notes:

- F-1600 Heavy Duty: Optimized for extreme pressure, temperature, and solids. Bonded urethane ensures longevity in abrasive slurries.

- FB-1600 Full-Open: Minimizes pressure drop for efficient mud circulation in ultra-deep drilling.

- Double Angle Valve: Compatible with API seats; snap-in inserts available in standard/high-temp versions.

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

What is a 4-Web Valve & Seat?

A 4-Web Valve & Seat is a heavy-duty valve system engineered for extreme-pressure mud pumping applications. Its unique four-support-web design provides superior structural stability and alignment under high cyclic loads, while the integrated seat ensures leak-free sealing in high-temperature drilling environments (up to 350°F/177°C).

Why choose 4-Web over other valve designs?

- Enhanced Durability: 4-web geometry distributes stress evenly, reducing cracking/peeling.

- Thermal Stability: Optimized for sustained performance in high-temperature wells (e.g., geothermal, deep drilling).

- Reduced Turbulence: Streamlined flow path minimizes erosion from abrasive mud.

- Easy Maintenance: Snap-in seat design allows quick replacement without disassembling the pump.

What materials handle high temperatures?

| Component | Material | Temperature Limit |

|---|---|---|

| Valve Body | Forged AISI 4140/4130 Steel | 350°F (177°C) |

| Sealing Surface | Stellite 6® or Tungsten Carbide | 400°F (204°C) |

| Seat Insert | Nitrided Steel + Ceramic Coating | 350°F (177°C) |

How does the 4-Web design improve valve life?

- Stress Reduction: 25% lower peak stress vs. 3-web designs (FEA-verified).

- Thermal Expansion Control: Web slots accommodate thermal growth without distortion.

- Debris Resistance: Self-cleaning groove design prevents particle jamming.

What applications suit 4-Web High-Temperature valves?

- Ultra-Deep Drilling (>15,000 ft)

- HTHP (High-Temperature High-Pressure) Wells

- Geothermal Drilling

- SAGD (Steam-Assisted Gravity Drainage) Operations

We are here to answer your questions and support your needs.