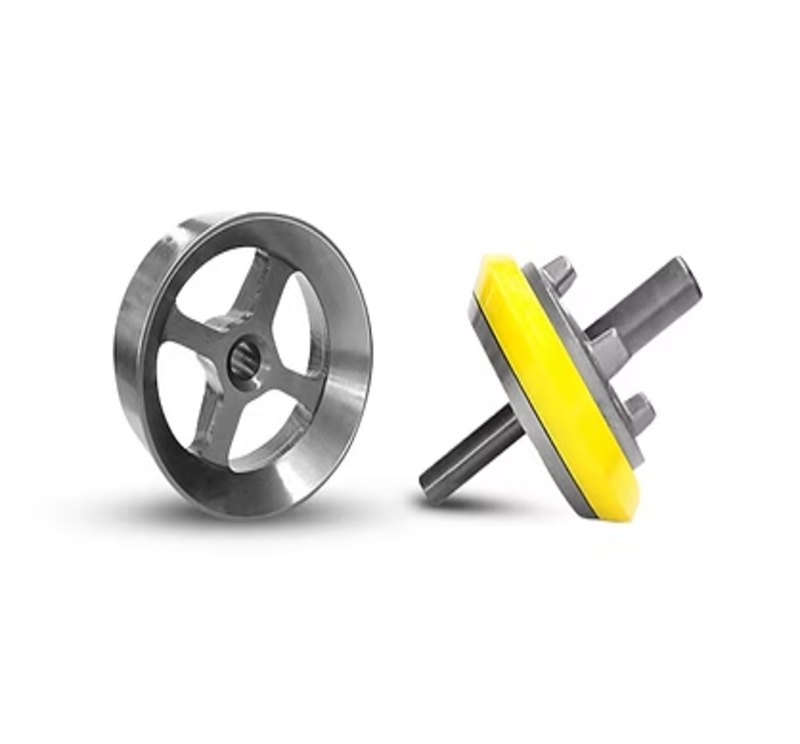

Mud Pump 4-Web Valve & Seat

Discover the power of our valve assemblies engineered to conquer the toughest drilling environments. Redefining efficiency and endurance.

Designed to withstand extreme pressures and abrasive conditions, our high-performance valve assemblies

ensure consistent, reliable operation, day in and day out. Whether you’re tackling deep wells or demanding

terrains, trust LC Mud Pumps to keep your mud pumps running stronger and longer.

Selling Points

- Enhanced Structural Stability and Durability

- Optimized Flow Dynamics and Efficiency

- Extended Service Life and Maintenance Convenience

- Versatility and Compliance

parameter

- Preassure rate: 7500 psi (seat)

- Temperature rate: 160°F (Std Insert)

- Bore Hardness: Water and synthetic- based

- API sizes: 6-1/4" to 7-1/2"

Feature

The 4-Web Valve & Seat is a specialized component designed for high-pressure mud pump systems, primarily used in oil & gas drilling, mining, and construction industries. It features a multi-web guided structure to ensure stable operation under extreme conditions such as high pressure, high temperature, and abrasive slurry environments. The valve and seat assembly is critical for controlling mud flow in circulating systems, ensuring efficient pumping and preventing leakage .

Key Technical Parameters

Parameter Specification Design Pressure 5,000–7,500 psi (34.5–51.7 MPa) 1 Temperature Range -20°C to 200°C (standard version); high-temperature options available 1 Material – Valve Body: Forged steel or 20CrMnTi alloy

– Valve Seat: Stainless steel

– Sealing Insert: High-temperature bonded urethaneConnection Type Threaded (API standard) Structure Feature 4-Web center-guided design with replaceable snap-in inserts Corrosion Resistance Oxide-coated surface for anti-corrosion during storage Applications Oil & gas drilling mud pumps, slurry pumps in mining/construction Core Advantages

- Enhanced Stability: The 4-web guided structure provides superior alignment and reduces vibration, minimizing wear on the valve seat and extending service life .

- High Durability: Constructed with forged steel and 20CrMnTi alloy, the valve resists abrasion and deformation under high-pressure conditions .

- Easy Maintenance: Replaceable snap-in inserts allow quick on-site repairs, reducing downtime .

- API Compliance: Compatible with standard mud pump models, ensuring interchangeability with OEM parts .

Explore Our BI-METAL LINER

Due to the limited information in the provided search results, specific models of the Mud Pump 4-Web Valve & Seat cannot be accurately listed. However, based on industry common practices and related product characteristics (e.g., from 2), typical models of mud pump valves often include specifications aligned with pump power, pressure ratings, and API standards. Below is a hypothetical reference table based on general industry conventions (for illustrative purposes only):

| Model | API Standard | Max Working Pressure | Valve Diameter (in) | Material | Application |

|---|---|---|---|---|---|

| F-1600HD-4W | API 7K | 7,500 psi | 4.5 | Bonded Urethane + Steel | High-pressure oil & gas drilling |

| FB-1600M-4W | API 7K | 5,000 psi | 3.0 | High-Temp Urethane | Medium-pressure mud circulation |

| Mission 9700250 | API 7K | 6,000 psi | 5.0 | Forged Alloy Steel | Offshore drilling rigs |

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

1. What is the structural feature of the 4-Web Valve & Seat?

The 4-Web Valve & Seat is a center-guided valve system characterized by its 4-web design, which enhances stability during high-pressure operation. It typically includes a replaceable snap-in insert (available in standard and high-temperature versions) and is oxide-coated to prevent corrosion during storage. The valve body and seat are often made of forged steel or 20CrMnTi material for durability, ensuring compatibility with API standards for seamless integration with mud pump systems

2. What temperature and pressure ranges does the 4-Web Valve & Seat support?

This valve system is engineered to handle extreme drilling conditions, with standard versions suitable for temperatures up to 121°C (250°F) and high-temperature variants rated for higher thresholds (specifics may vary by manufacturer). Pressure resistance typically aligns with high-pressure mud pump requirements, ranging from 5,000 to 7,500 psi (34.5 to 51.7 MPa), making it ideal for oil & gas, mining, and construction applications involving high-solids mud

3. How to maintain and replace the 4-Web Valve & Seat?

Maintenance involves regular inspection of the valve insert, seat, and coating for wear or corrosion. The replaceable snap-in insert allows for quick更换 without disassembling the entire valve body, reducing downtime. Ensure proper torque when reinstalling to prevent leaks, and use manufacturer-recommended lubricants for threaded connections. Storage in dry conditions is advised to preserve the oxide coating’s corrosion resistance

4. What applications are 4-Web Valves suitable for?

They are ideal for hostile drilling environments including:

5. How to select the right 4-Web Valve for a mud pump?

- Pressure/Temperature Ratings: Choose standard (ambient) or high-temperature (HT) inserts based on well conditions.

- API Compliance: Ensure compatibility with API-standard valve seats.

- Pump Model: Match dimensions to specific pump models (e.g., F-1600, 16P160).

- Material Selection: Urethane inserts for abrasion resistance; metal alloys for extreme pressure

We are here to answer your questions and support your needs.