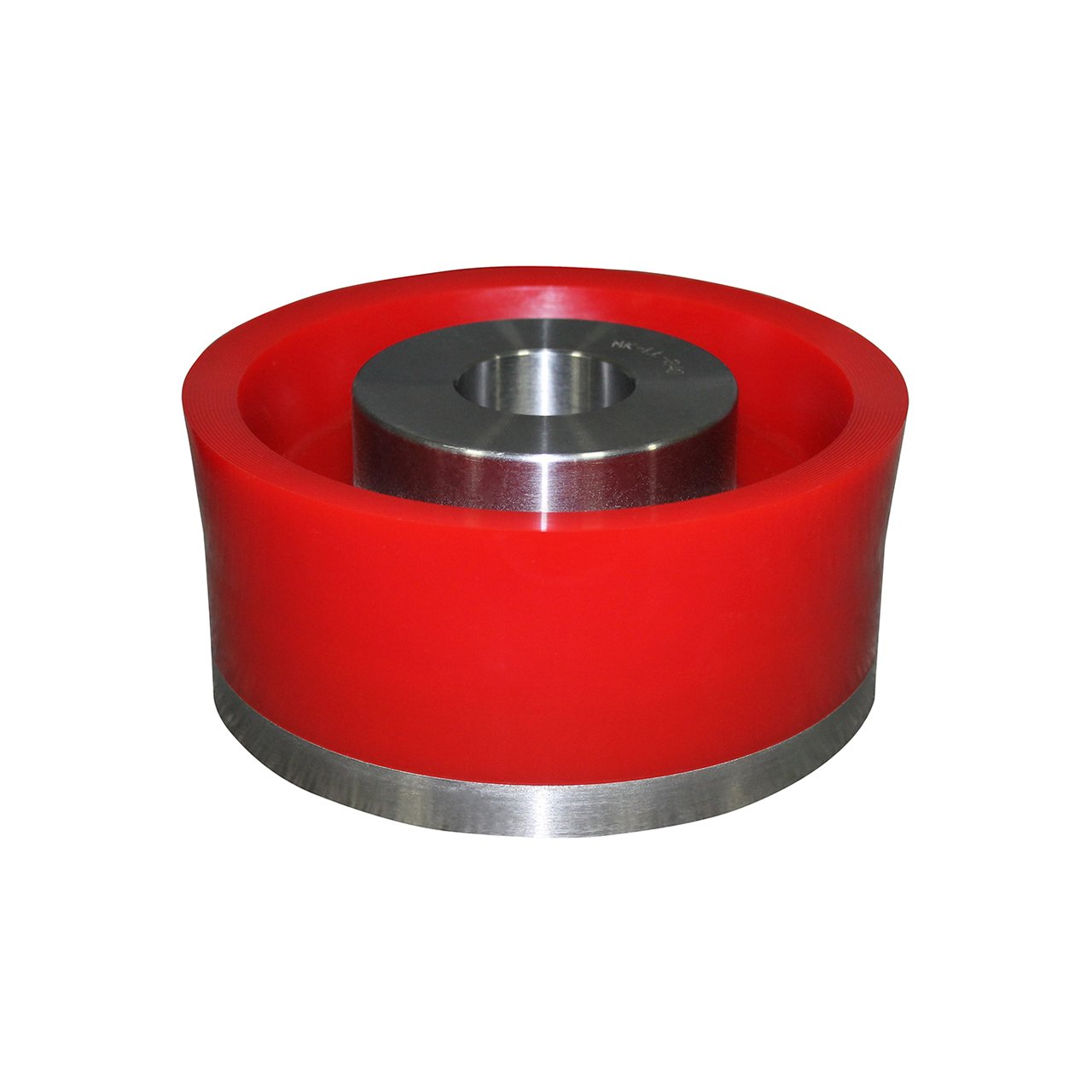

Mud Pump Rubber Bonded Piston

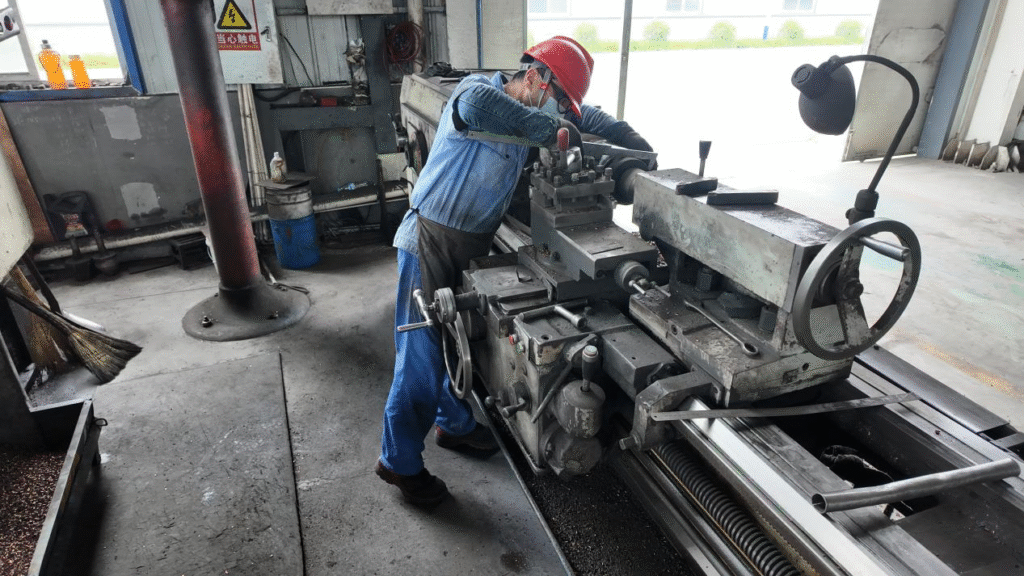

Crafted with the highest standards, our rubber bonded pistons are manufactured using premium materials and cutting-edge technology. This ensures that each liner is robust, reliable, and built to last in the most demanding drilling environments.

Our pistons are designed with meticulous attention to detail, providing a perfect fit and smooth operation every time, making our rubber bonded pistons the best choice for operations that demand uncompromising performance.

Selling Points

- Enhanced Structural Integrity

- Superior Sealing Performance

- Abrasion and Corrosion Resistance

- Cost-Effective Maintenance

Suitable Subtitle

- Preassure rate: 5,000 psi

- Temperature rate: 200F

- Suitable for: Water/Synthetic based mud

Feature

- Application: Triplex and duplex mud pumps in oilfield drilling rigs

- Function: Transfers drilling fluid (mud) by creating suction and discharge cycles through reciprocating motion in the fluid end

- Design Type: Bonded (non-replaceable rubber) – rubber is vulcanized onto the steel piston core

- Common Standards: API 7K, ISO 9001 certified

- Typical Pump Brands Compatible: Gardner Denver, NOV (National Oilwell Varco), Rigstar, Sundyne, PZ Series, etc.

Key Features

Feature Description Bonded Construction Rubber is chemically bonded (vulcanized) to the steel core for improved durability and resistance to separation under high pressure High Wear Resistance Specially formulated rubber resists abrasion from sand and solids in drilling mud Sealing Efficiency Provides excellent sealing against the liner wall, minimizing fluid slippage and maintaining pump efficiency Corrosion Resistant Core Steel core is often chrome-plated or coated to resist corrosion from acidic or saline mud Temperature Resistance Operates effectively in a wide temperature range (typically -20°C to +90°C / -4°F to 194°F) Common Technical Parameters

Parameter Specification Piston Sizes (Diameter) 3.5″, 4.0″, 4.5″, 5.0″, 5.5″, 6.0″, 6.5″, 7.0″ (common sizes) Rubber Material Options Nitrile Rubber (NBR), Hydrogenated Nitrile (HNBR), Polyurethane (PU), or custom blends Working Pressure Up to 35 MPa (5,000 psi), depending on pump model and size Max Stroke Rate Up to 120–150 strokes per minute (SPM), depending on pump design Compatibility F-800, F-1000, F-1300, F-1600, PZ-7, PZ-8, PZ-9, PZ-10, 3NB series, etc. Connection Type Threaded shank (e.g., 1-1/4″ REG, 1-1/2″ REG) to fit standard piston rods Liner Compatibility Designed to match standard ceramic or alloy steel liners Service Life Varies with operating conditions; typically 200–500 hours under normal drilling conditions Advantages of Bonded Pistons vs. Replaceable Pistons

Feature Bonded Piston Replaceable (Screw-in) Piston Durability Higher – no risk of rubber loosening Lower – rubber can unscrew during operation Sealing Performance Superior – consistent contact with liner Good, but may degrade if screw loosens Maintenance Entire piston replaced when worn Only rubber element replaced Cost Higher initial cost Lower initial cost, but more frequent service Best For High-pressure, continuous operations Light to medium-duty or cost-sensitive operations Typical Applications

- Oil and gas well drilling

- Horizontal directional drilling (HDD)

- Mud circulation systems

- Pressure testing units

Maintenance Tips

- Inspect pistons regularly for signs of wear, cracking, or chunking.

- Ensure proper lubrication of the fluid end.

- Avoid dry running – always prime the pump before operation.

- Match piston hardness to mud conditions (softer rubber for cleaner mud, harder for abrasive mud).

Suppliers & Standards

- Complies with API 7K (Equipment Classification for Well Servicing and Drilling)

- Manufactured by leading brands such as Gardner Denver, NOV, and specialized OEMs

- Available with OEM part number cross-references

Explore Our BI-METAL LINER

| Parameter | Details | Source |

|---|---|---|

| Compatible Brands | Gardner Denver (PZ7/PZ8/PZ9/PZ10, F1300/F1600 series) | |

| Piston Sizes | 3-1/2″, 4-1/2″, 5-1/2″, 6-1/2″ | |

| Model Numbers | • 3-1/2″: MT-134HK14/15 • 4-1/2″: MT-150HB14/15, MTB-500, MTU-500 • 5-1/2″: Model specified per pump | 1 |

| Material Options | Bonded rubber/urethane composites | |

| Certifications | API 7K/ISO standards | 12 |

| Structural Type | Bonded design (permanent adhesion to metal core for enhanced stability) | |

| Supply Capacity | Up to 20,000 sets/month |

Key Notes:

- Size-Specific Models: Bonded pistons use unique codes (e.g., MTB-500 for 4-1/2″ pistons).

- Material Advantage: Bonded urethane/rubber offers superior wear resistance vs. replaceable types

- Compatibility: Designed for triplex mud pumps; verify pump model compatibility before selection.

Mud Pump Rubber Bonded Pistons FAQ

1. What are Mud Pump Rubber Bonded Pistons?

Mud pump rubber bonded pistons are critical components in drilling mud pumps, designed with a permanent bond between the rubber/urethane elastomer and a metal core 12. This integrated structure eliminates potential leak points, enhancing durability and performance in high-pressure drilling fluid circulation systems. They are primarily used in triplex mud pumps for oil and gas well drilling

2. What Materials Are Used in Bonded Pistons?

3. Key Specifications

| Parameter | Details |

|---|---|

| Pump Compatibility | GARDENER DAVER (PZ7/PZ8/PZ9/PZ10 series), triplex mud pumps 1 |

| Sizes Available | 4-1/2 inches (e.g., MT-144HK14/15, MT-150HB14/15) 1 |

| Certifications | API-certified to meet oilfield industry standards 12 |

| Design Advantage | No joints to prevent fluid leakage; interchangeable with replaceable rubber pistons 2 |

4. How Do Bonded Pistons Differ from Replaceable Pistons?

We are here to answer your questions and support your needs.