Mud Pump Replaceable Rubber piston

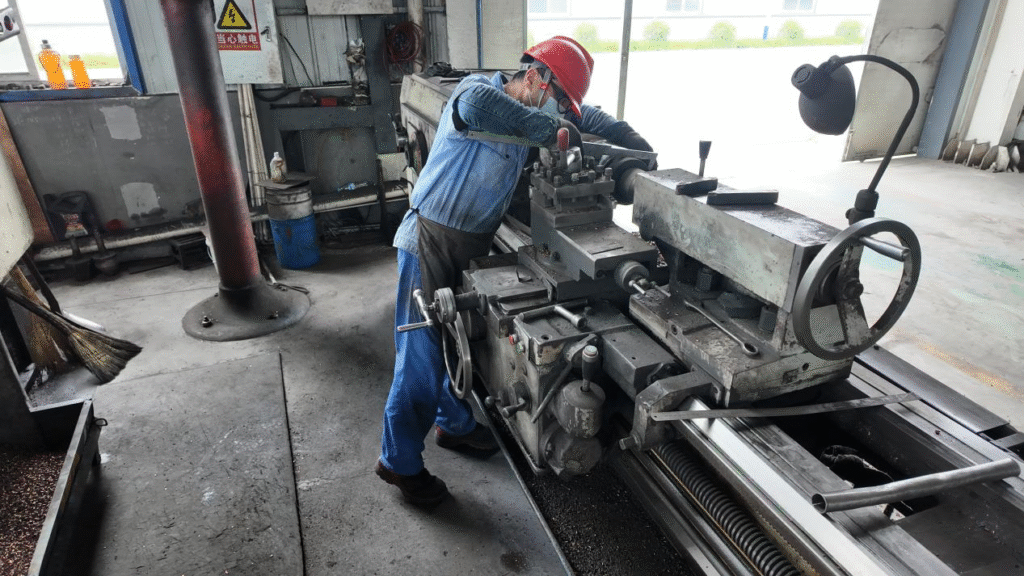

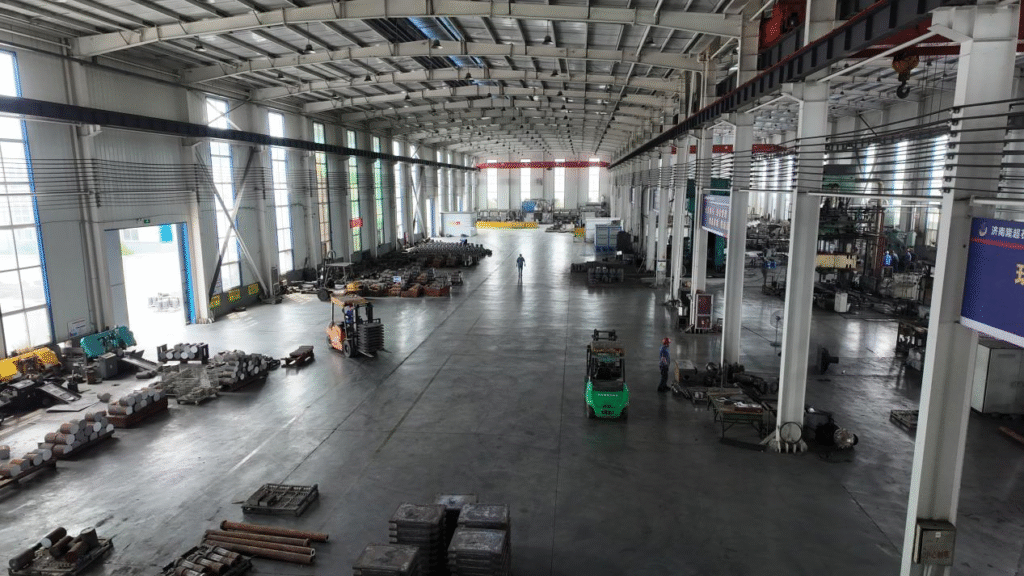

Crafted with the highest standards, our replaceable rubber pistons are manufactured using premium materials and cutting-edge technology. This ensures that each liner is robust, reliable, and built to last in the most demanding drilling environments.

Our pistons are designed with meticulous attention to detail, providing a perfect fit and smooth operation every time, making our replaceable rubber piston the best choice for operations that demand uncompromising performance.

Selling Points

- Cost-Efficient Maintenance

- Enhanced Durability in Abrasive Environments

- Optimal Sealing Performance

- Easy Installation and Compatibility

Suitable Subtitle

- Preassure rate: 5,000 psi

- Temperature rate: 200F

- Suitable for: Water/Synthetic based mud

Feature

A replaceable rubber piston is a critical component used in mud pumps, which are essential in oil and gas drilling operations. These pistons are designed to reciprocate within the pump cylinder, facilitating the movement of drilling fluid (mud) through the system. The replaceable design allows for easy maintenance and replacement, minimizing downtime and maximizing efficiency.

Product Description

- Application: Used in mud pumps for oil and gas drilling operations.

- Material Options:

- Rubber

- Urethane

- Bonded urethane/rubber

- Certifications:

- API (American Petroleum Institute)

- ISO

- Warranty: 1-year warranty with access to free parts replacement and repair coverage.

- Operating Temperature: Up to 180°F (82.2°C) 3.

- Sealing Mechanism: Features a sealing lip and heel, with the lip having an uncompressed diameter that is at least 0.20 inches larger than the inside diameter of the cylinder for enhanced sealing 4.

Technical Parameters

Parameter Details Pump Models Supported GARDENER DAVER, PZ7/PZ8/PZ9/PZ10, F1300, F1600, F1600HP, BOMCO, IDECO Piston Sizes Available 3-1/2″, 4-1/2″, 5-1/2″, 6-1/2″ Types Replaceable, Bonded Urethane Material Standards NBR (Nitrile Butadiene Rubber), HNBR (Hydrogenated Nitrile Butadiene Rubber), Urethane 3 Core Material 42CrMo (alloy steel) Sealing Reinforcement Outer peripheral surface reinforced with a flexible layer of fluoride rubber (2–5 mm thick) 1 Design Features – No annular depression on the outer surface

– No separate retaining means for the heel 4Advantages

- Durability: Enhanced wear resistance due to reinforced rubber or urethane materials.

- Easy Replacement: Designed for quick and tool-free replacement, reducing maintenance time 2 .

- High Reliability: Improved sealing performance and operational reliability due to advanced lip and heel design 1 .

- API Certification: Ensures compliance with industry standards for performance and safety 2 .

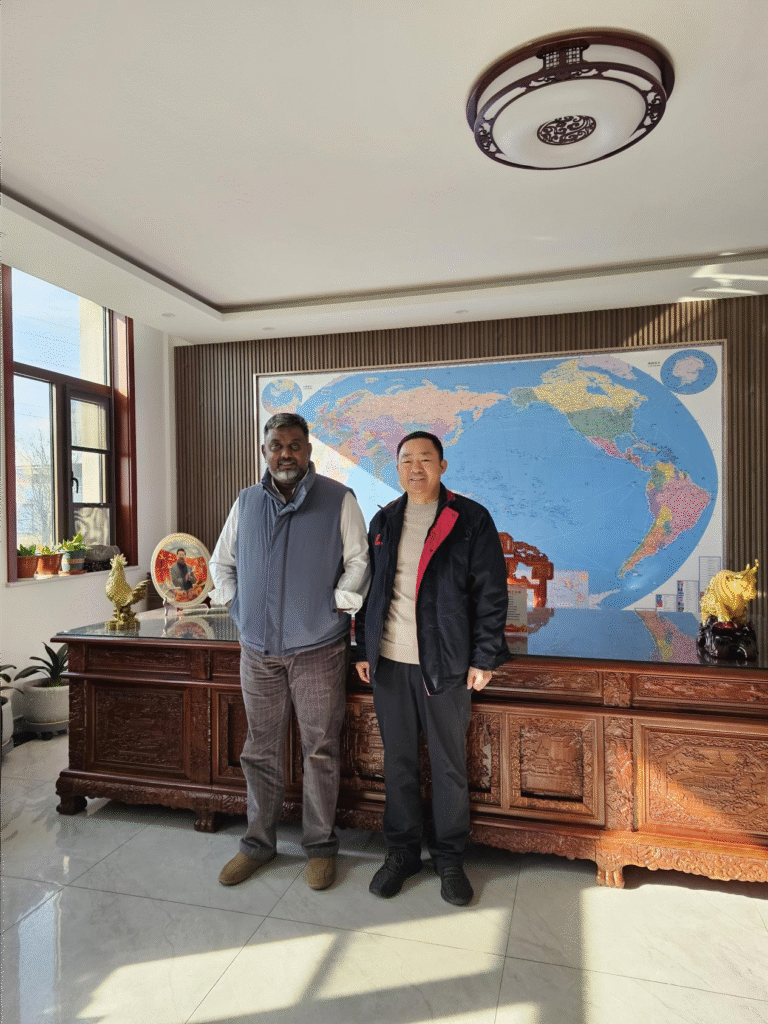

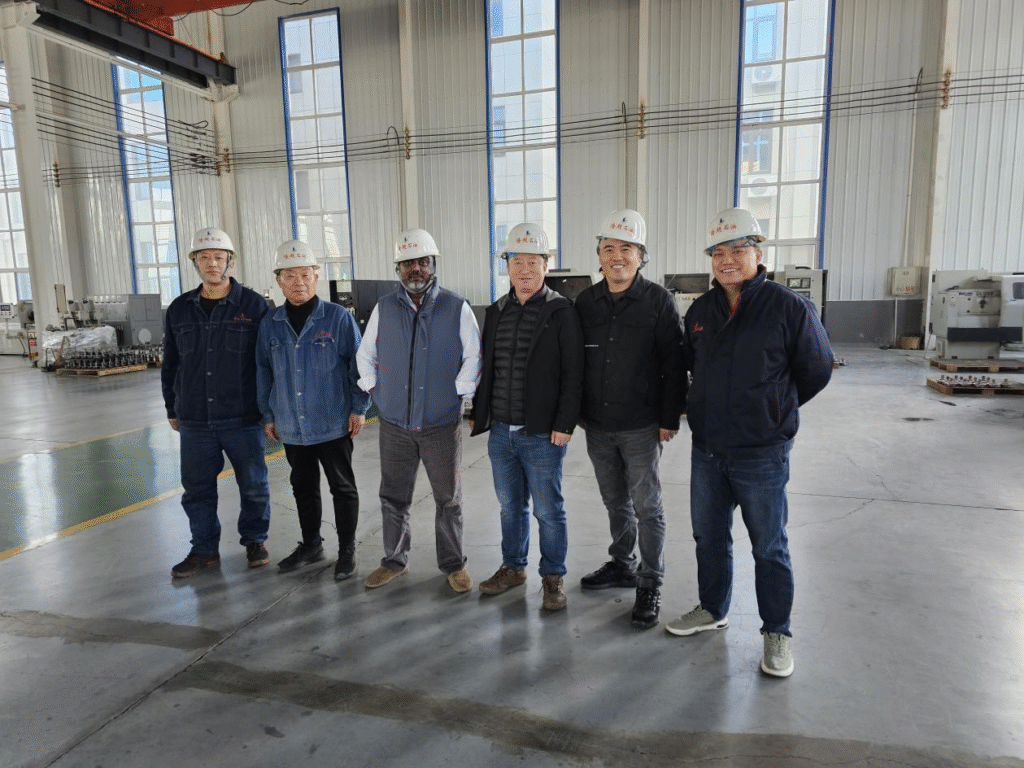

Suppliers and Availability

- Manufacturer: Beijing Ocean Renda Petroleum Equipment Co., Ltd.

- Markets Served: South America, United States, Colombia, Mexico, Dubai 2 .

- Port of Shipment: Qingdao or Tianjin, China 3 .

- Order Quantity: 10–499 pieces per order 3 .

Explore Our BI-METAL LINER

| Parameter | Details | Reference |

|---|---|---|

| Material Types | Rubber, Polyurethane, Bonded Urethane/Rubber composites | |

| Structural Design | Replaceable (easy maintenance), Bonded (enhanced stability) | [History] |

| Operating Pressure | Suitable for high-pressure drilling environments (especially polyurethane) | |

| Primary Function | Reciprocating movement to transport drilling fluid, cooling drill bits, and clearing cuttings | |

| Key Maintenance | Requires regular inspection; avoid debris ingress; lubricate with high-pressure water |

Notes:

- Material Selection:

- Rubber: Cost-effective for standard conditions.

- Polyurethane: Superior abrasion resistance in high-pressure/high-wear scenarios .

- Operational Precautions:

- Ensure exact size matching (e.g., diameter tolerance ≤0.5mm) to prevent efficiency loss .

- Always use clean fluids to extend service life .

- Applications:

- Oil/gas drilling, mining slurry handling, and industrial fluid transfer in harsh environments .

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

1. What is a mud pump replaceable rubber piston?

A mud pump replaceable rubber piston is a wear component used in reciprocating positive displacement mud pumps in oil and gas drilling operations. It consists of a metal piston core and a rubber (or polyurethane) sealing element that can be replaced when worn, extending the life of the piston assembly.

2. What is the main function of the rubber piston?

The rubber piston creates a tight seal between the piston head and the liner (cylinder) of the mud pump. As the piston moves back and forth, it pressurizes and displaces drilling fluid (mud) through the pump, ensuring efficient circulation downhole.

3. What materials are used in replaceable rubber pistons?

- Rubber: Typically nitrile rubber (NBR) or hydrogenated nitrile rubber (HNBR), offering good resistance to oil, abrasion, and moderate temperatures.

- Polyurethane (PU): Provides higher wear resistance and longer life in abrasive or high-pressure conditions.

- Bonded Rubber/PU: A combination where rubber or urethane is bonded to a steel piston core for durability.

4. What are the advantages of a replaceable design?

- Cost-effective: Only the rubber/urethane sleeve needs replacement, not the entire piston assembly.

- Reduced downtime: Faster replacement in the field without removing the piston rod.

- Extended core life: The steel core can be reused multiple times.

5. Which mud pump models are compatible?

Commonly fits triplex and quintuplex mud pumps such as:

- Gardner Denver (PZ-7, PZ-8, PZ-9, PZ-10, PZ-13)

- NOV (3NB1300, 3NB1600, F-800, F-1000, F-1300, F-1600)

- Shenyang, SPM, and other OEM equivalents

We are here to answer your questions and support your needs.