Mud Pump HT400 Module

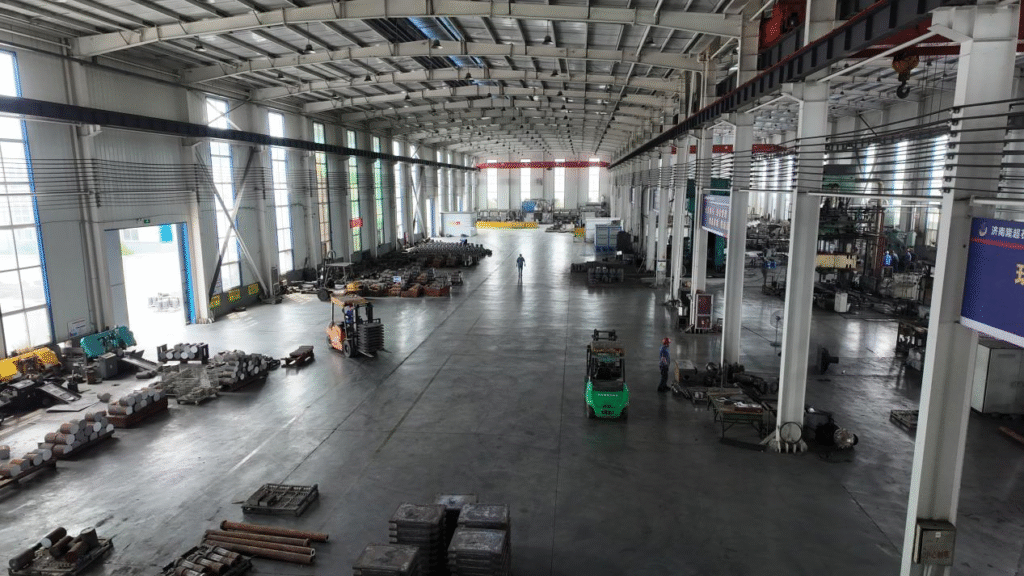

- Core Function: As a module for mud pumps, it likely integrates components such as fluid end blocks, liners, pistons, or valves to facilitate the pumping of drilling mud or slurry. Mud pump modules are essential for maintaining high-pressure fluid transfer in harsh environments like oilfield drilling and mining operations .

- Compatibility: It may be designed for use with triplex or quintuplex mud pumps, given that such configurations are highlighted in industry offerings (e.g., “Triplex Pump,” “Quintuplex Pump”)

Selling Points

- High Power and Versatility

- Interchangeable Components for Reduced Costs

- Durable Materials Ensuring Longevity

- Comprehensive Spare Parts Availability

Feature

- Application Scope: Primarily used in petroleum machinery, specifically in mud pumps for drilling rigs. It is compatible with various mud pump models, including those requiring high-strength fluid end components to handle abrasive drilling mud2.

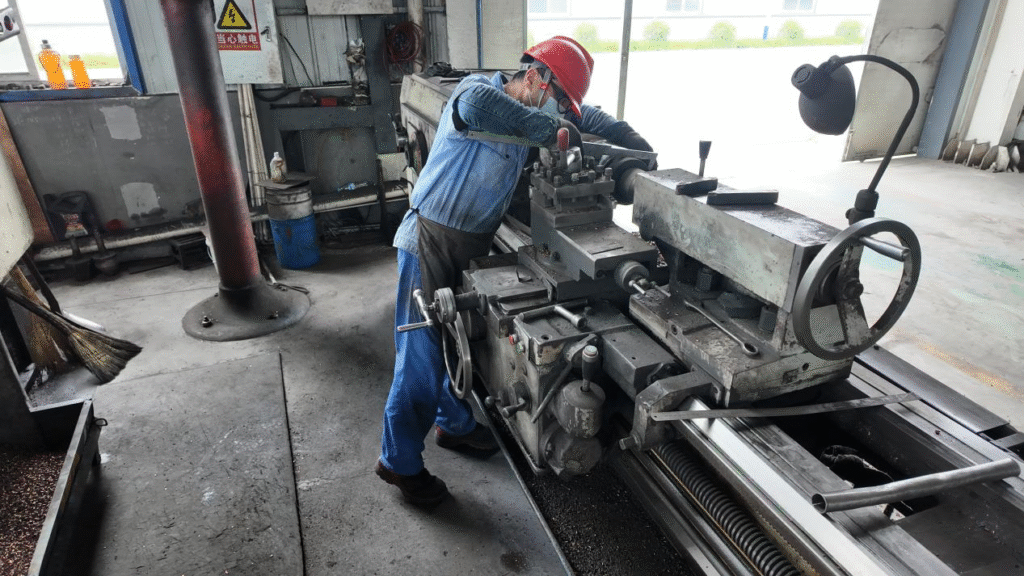

- Material Specification: Constructed from HT400, a high-tensile cast iron material known for its excellent wear resistance and mechanical strength. This material is suitable for harsh operating environments involving high pressure and solid-laden fluids2.

- Functional Role: As a fluid end spare part, the HT400 module works in conjunction with other components such as plungers, pistons, and cylinder liners to maintain the integrity of fluid flow and pressure during mud circulation2.

Technical Parameters (Typical Specifications)

Parameter Description Product Category Mud Pump Fluid End Spare Parts Material HT400 (High-Tensile Cast Iron) Compatible Pump Types Bomco Mud Pumps, Triplex Mud Pumps, and other drilling rig mud pumps2 Application Industry Oil and Gas Drilling, Petroleum Machinery Supplier Type Professional Manufacturer/Exporter (China-based suppliers common)2 Notable Features

- High Pressure Resistance: Engineered to withstand the extreme pressure conditions typical in drilling operations, ensuring long-term reliability.

- Wear Resistance: HT400 material minimizes wear from abrasive mud particles, extending component lifespan.

- Interchangeability: Designed as a standardized spare part for easy replacement and compatibility with multiple mud pump models2.

Mud Pump HT400 Module FAQ

1. What is the HT400 Mud Pump Module?

The HT400 is a horizontal triplex mud pump module designed by Halliburton, originally introduced in 1957. Its name derives from “Horizontal Triplex” and an initial 400-horsepower rating. Over time, design upgrades have increased its maximum power to 800 hp in certain configurations. It is widely used in fracturing, acidizing, and cementing operations, known for being lightweight, rugged, and versatile

2. What are the key applications of the HT400 Module?

The HT400 module is primarily used in oil and gas field operations, including:

- Fracturing: Pumping fracturing fluids at high pressure to stimulate reservoirs.

- Acidizing: Injecting acid to enhance well productivity.

- Cementing: Delivering cement slurries for wellbore isolation

3. What improvements have been made to the HT400 since its debut?

Since 1957, the HT400’s basic design has undergone significant upgrades, most notably an increase in power rating from the original 400 hp to a maximum of 800 hp in specific configurations. These improvements enhance its performance and durability for modern drilling demands

4. Is the HT400 compatible with other mud pump components?

While specific compatibility details are not fully provided in the references, mud pumps like the HT400 typically integrate with standard components such as replaceable rubber pistons, cylinder liners, and drive systems. For precise part compatibility, consult Halliburton’s technical documentation or supplier specifications

5. What maintenance considerations apply to the HT400 Module?

As a high-pressure triplex pump, regular maintenance focuses on:

- Inspecting and replacing wear parts (e.g., pistons, valves).

- Monitoring hydraulic connections for leaks.

- Ensuring proper alignment of the horizontal triplex configuration to prevent premature wear. Refer to the manufacturer’s guidelines for detailed maintenance schedules

We are here to answer your questions and support your needs.