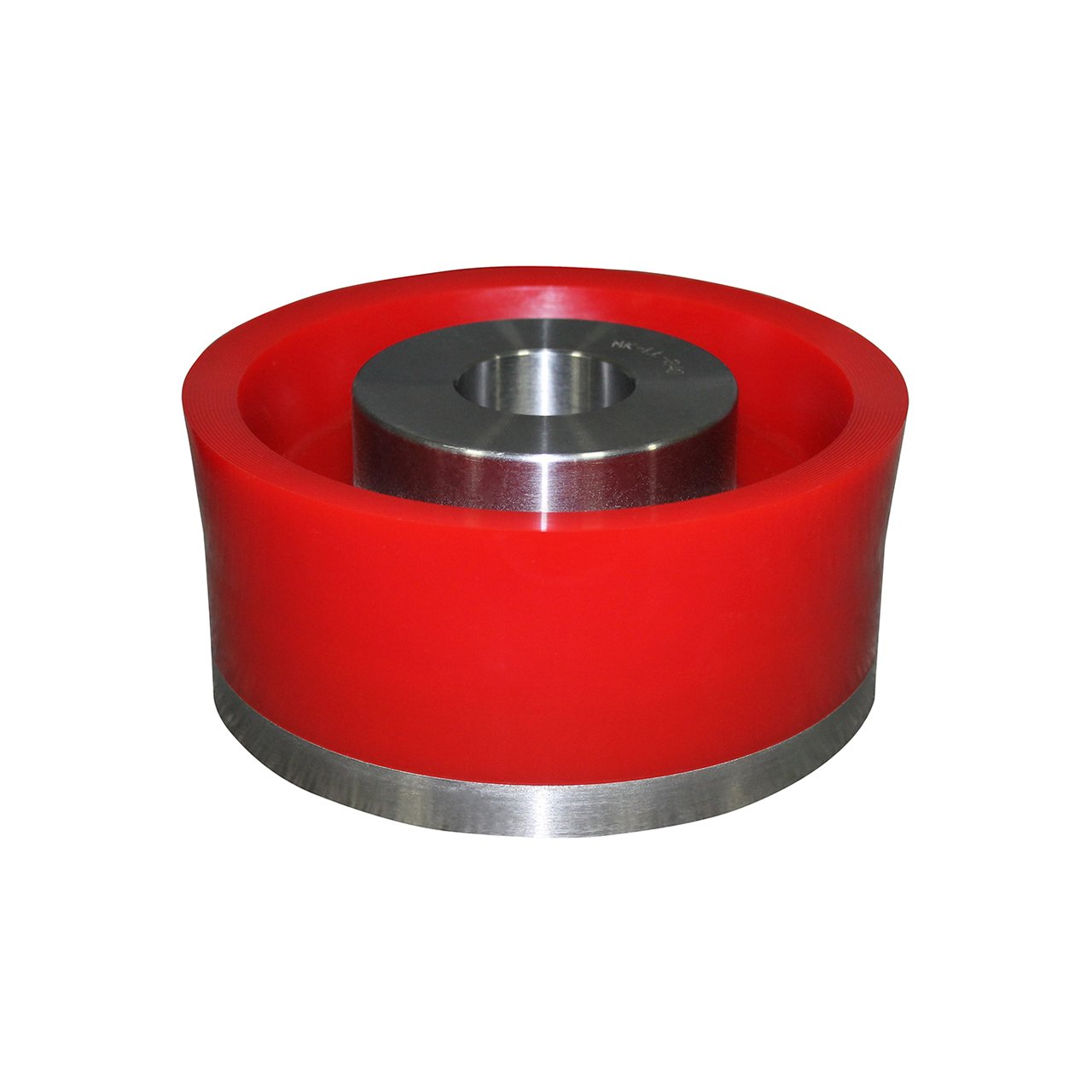

Mud Pump High temperature urethane bonded piston

Built for extreme durability, RedRock HT urethane pistons redefine reliability in mud pump performance. Redefining efficiency and endurance, these high-performance liners offer superior resistance to wear, corrosion, and thermal stress—ensuring maximum longevity in the most demanding drilling environments.

Our pistons are designed with meticulous attention to detail, providing a perfect fit and smooth operation every time, making our HT urethane bonded pistons the best choice for operations that demand uncompromising performance.

Selling Points

- Enhanced Structural Integrity

- Superior Sealing Performance

- Abrasion and Corrosion Resistance

- Cost-Effective Maintenance

Basic parameters

- Preassure rate: 7,500 psi

- Temperature rate: 350F

- Suitable for: Oil, Synthetic and Water Muds

Feature

High-temperature urethane bonded pistons are specialized components for mud pumps used in extreme drilling conditions (e.g., deep wells, geothermal operations). Unlike replaceable rubber pistons, these are permanently bonded to the piston rod using advanced adhesives, ensuring structural integrity under high pressure and heat. Urethane offers superior abrasion resistance, chemical stability, and thermal endurance compared to standard rubber.

⚙️ Key Features

Material Composition:

- Polyurethane (urethane) compound, chemically engineered for temperatures up to 250°F (121°C).

- Enhanced additives for resistance to drilling fluids (oil-based/synthetic muds), H₂S, and abrasives.

Bonding Technology:

- Epoxy-bonded design: Creates a monolithic unit with the piston rod, eliminating slippage or detachment risks.

- Superior fatigue resistance under cyclic pressure loads (up to 7,500 psi).

Performance Advantages:

- 3–5× longer lifespan than rubber pistons in high-temperature environments.

- Minimal swelling/degradation in corrosive fluids.

📊 Technical Parameters

Parameter Specification Operating Temp Range -40°F to 250°F (-40°C to 121°C) Pressure Rating Up to 7,500 psi (517 bar) Compatible Pump Models Gardner Denver PZ series, F-1000/F-1600, TSC 3NB/5NB, NOV P-220/P-300 Standard Sizes 3″–7″ (76–178 mm) diameter; Custom sizes available Certifications API 7K/ISO 9001 (Quality), API 16C (Blowout Preventer Compatibility) Service Life 300–600 operating hours (dependent on mud abrasivity & temperature) Supplier Note

Leading manufacturers (e.g., Schlumberger, NOV, Weir Group) offer custom formulations for specific conditions. Consult technical datasheets for fluid compatibility graphs and pressure-temperature derating curves.

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

1. What is a High-Temperature Urethane Bonded Piston?

A high-temperature urethane bonded piston is a specialized component for mud pumps, designed to withstand extreme drilling conditions. It combines a urethane elastomer bonded to a metal substrate (e.g., steel or alloy) to balance flexibility, abrasion resistance, and thermal stability. This design ensures reliable performance in high-pressure (up to 7,500 psi/51.7 MPa) and high-temperature environments

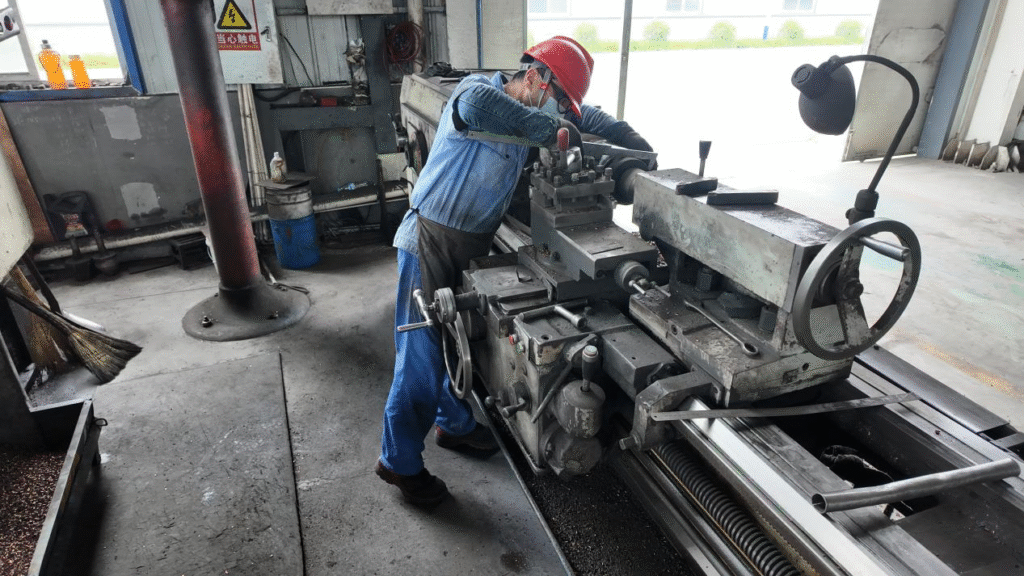

2. What Materials Are Used in Its Construction?

- Urethane Elastomer: High-temperature resistant formulation to endure temperatures up to 200°C (varies by product).

- Bonded Substrate: Forged steel or 20CrMnTi alloy for structural strength, ensuring compatibility with pump cylinders 1.

- Additional Components: May include stainless steel valve seats or oxide-coated surfaces to prevent corrosion during storage

3. What Are Its Key Performance Advantages?

- High-Temperature Resistance: Operates effectively in environments exceeding standard temperature limits.

- Abrasion & Solids Handling: Superior resistance to wear from drilling mud containing high solids content 1.

- Longevity: Extended run life compared to standard rubber pistons, reducing downtime for replacements 1.

- Pressure Endurance: Engineered for high-pressure applications, critical for deep oil & gas drilling

4. What Industries and Applications Is It Suitable For?

Primarily used in oil & gas drilling, mining, and construction industries. Ideal for mud pumps in harsh conditions, such as:

- Deep-well drilling with high geothermal temperatures.

- Operations involving abrasive drilling fluids (e.g., slurry with sand or rock particles)

5. How Does It Differ From Standard Urethane Pistons?

- Temperature Range: Specifically formulated to resist degradation at higher temperatures (standard urethane may soften or crack).

- Bonding Technology: Advanced bonding processes ensure the urethane layer adheres securely to the metal substrate, preventing delamination under stress 1.

- Certifications: May comply with API standards or ISO 9001:2015 for quality assurance

We are here to answer your questions and support your needs.

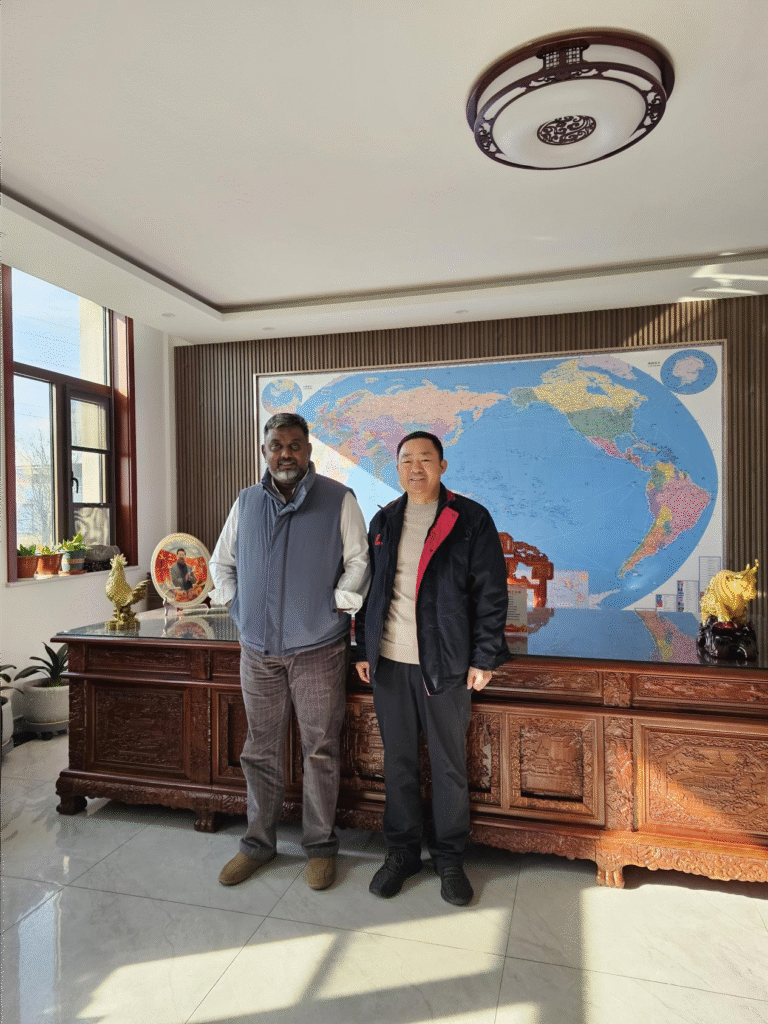

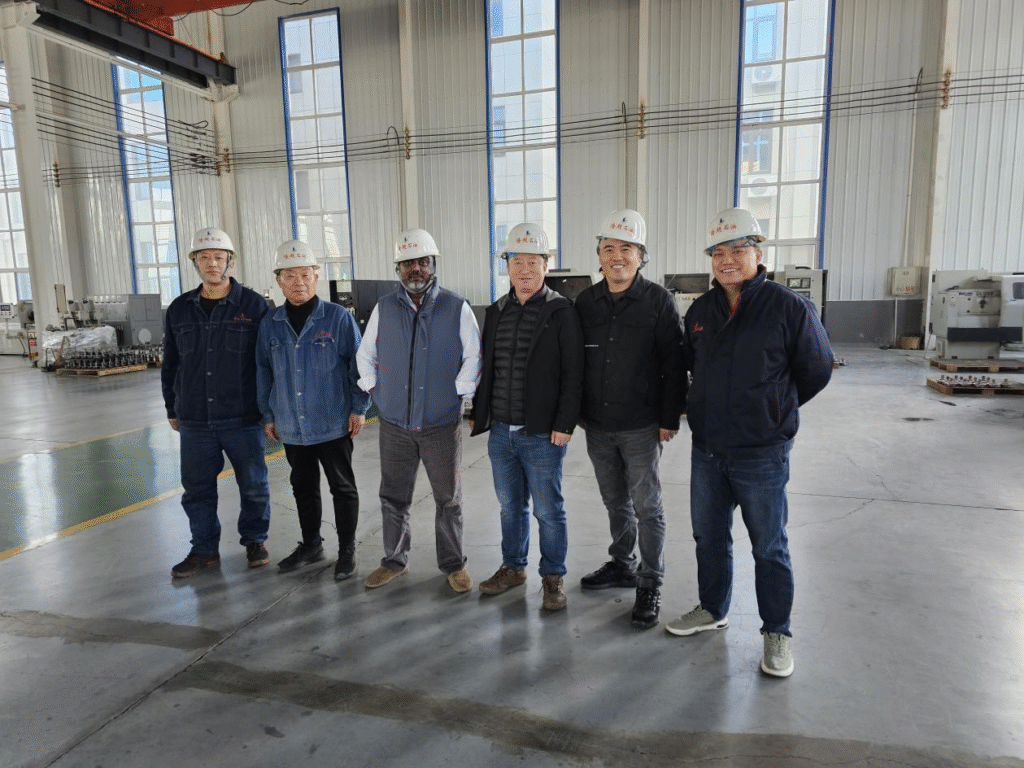

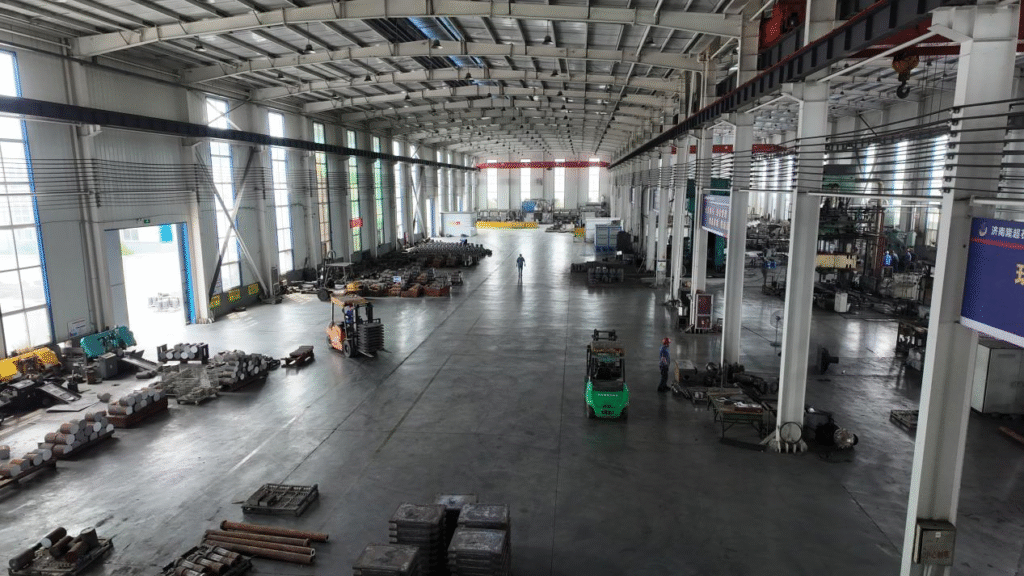

This is Longchao Petroleum Machinery Forging Co., Ltd. I highly recommend their products. Their factory is in China, a beautiful country. They’re a large company, with a large factory. The product quality is excellent. I’ve been working with them for over 10 years. Their products have made me a lot of money.

I buy from them frequently and their after-sales service is fast, which saves me a lot of money. I am really happy to have come across such a factory.