Full Open Valve High temperature

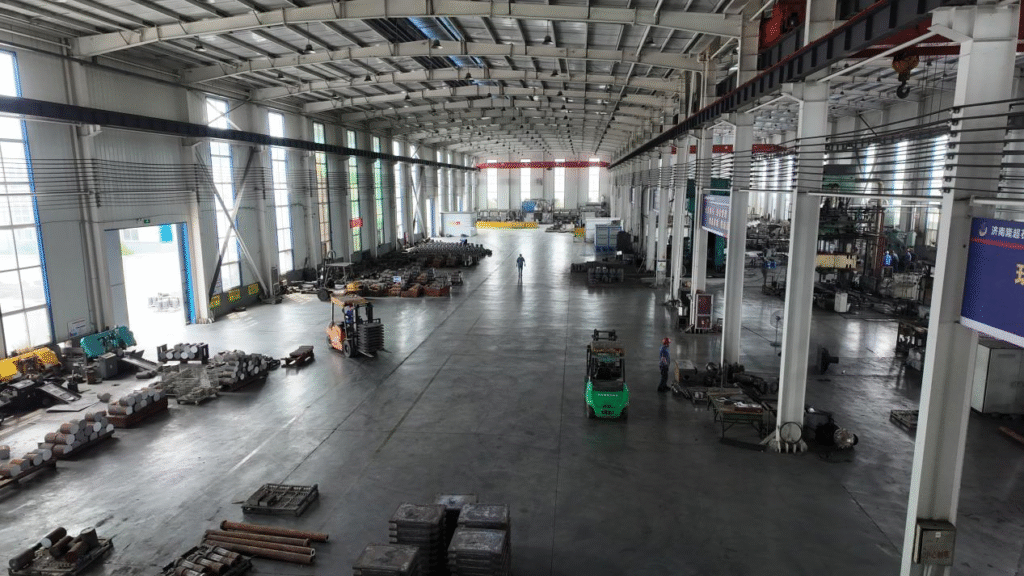

Discover the power of valves, the premier choice for valve assemblies engineered to conquer the toughest drilling environments. Redefining efficiency and endurance, valves sets a new industry standard with cuttingedge materials and precision craftsmanship that maximize performance while minimizing downtime.

Designed to withstand extreme pressures and abrasive conditions, our high-performance valve assemblies

ensure consistent, reliable operation, day in and day out. Whether you’re tackling deep wells or demanding

terrains, trust valves to keep your mud pumps running stronger and longer.

Selling Points

- Enhanced Flow Efficiency

- Improved Safety

- Versatile Applications

- Long-lasting Durability

Basic parameters

- Preassure rate: 7500 psi (seat)

- Temperature rate: 350°F

- Bore Hardness: Water and synthetic- based

- API sizes: 6-1/4 to 7-1/2

Feature

A Full Open Valve is a critical component in mud pump systems used in oil & gas drilling, mining, and construction industries. The high-temperature version is specifically engineered to perform reliably under extreme thermal conditions. This valve allows for complete flow passage when open, minimizing pressure drop and ensuring efficient fluid transfer. It is commonly used in high-pressure environments where thermal stress and abrasive media are prevalent .

Key Features

- High-Temperature Resistance: Designed to operate efficiently in environments exceeding standard operational temperature limits.

- Full Bore Design: Ensures unrestricted flow, reducing wear and erosion from abrasive drilling fluids.

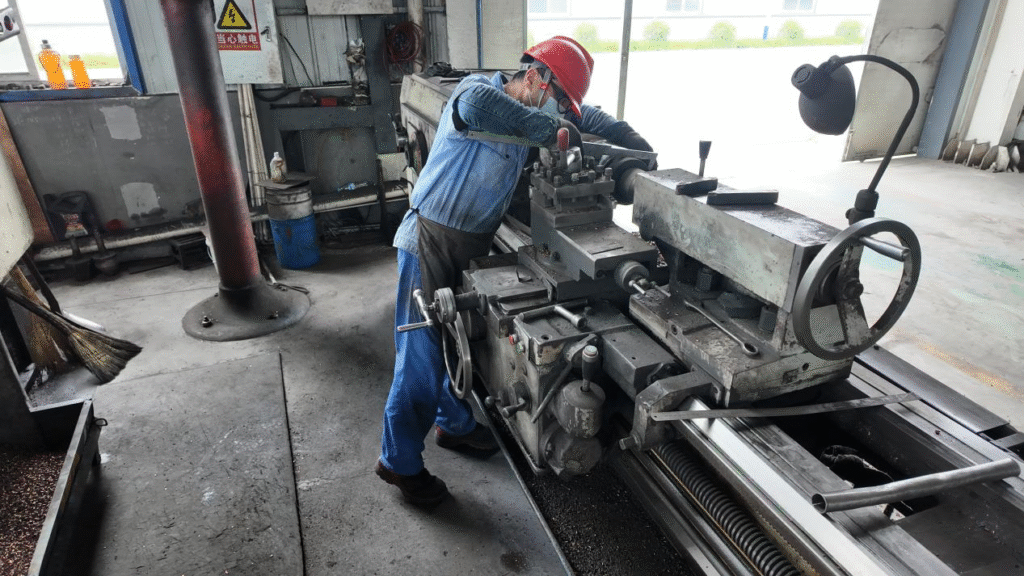

- Durable Material Construction: Typically made from heat-treated alloys or stainless steel to withstand thermal expansion and corrosion.

- Easy Maintenance: Modular design allows for quick replacement and servicing, reducing downtime .

Technical Parameters

Parameter Description Nominal Size 2″ – 6″ (varies by manufacturer) Pressure Rating Up to 10,000 psi (70 MPa) Temperature Range -20°C to +300°C (standard high-temp version) Material Options Stainless Steel (e.g., SS316), Alloy Steel, Chrome-Moly Steel End Connections API 6A or custom flanged connections Valve Type Gate Valve or Ball Valve (Full Port Design) Sealing Type Metal-to-metal or resilient seated, depending on application Application Drilling rigs, well servicing, fracturing units, and high-pressure mud circulation systems These valves are often tested and certified to meet industry standards such as API 6A and ISO 10423, ensuring performance under severe service conditions .

Mud Pump Full Open Valve High Temperature

| Model Series | Max Temp (°C) | Pressure Rating (MPa) | Flow Capacity (m³/h) | Material | Key Features |

|---|---|---|---|---|---|

| HT-FOV300 | 180 | 35 | 120 | Chrome Alloy Steel | Unrestricted bore, ceramic-coated seats |

| HT-FOV450 | 200 | 50 | 180 | Inconel 625 | Anti-coking design, thermal shock resistant |

| HT-FOV600 | 220 | 70 | 250 | Tungsten Carbide | Zero-pressure-drop flow, integrated cooling fins |

| KSL-HV800 | 150 | 40 | 300 | Duplex Stainless Steel | Self-priming capability 2, debris-resistant |

| Custom-X Series | 250 | 100+ | 500+ | C276 Hastelloy | Tailored flange interfaces, multi-seal system |

Critical Parameters Explained

Thermal Resilience

- Operates continuously at 150–250°C 1, with peak tolerance up to 300°C (short-term).

- Ceramic/Tungsten coatings prevent thermal deformation.

Flow Dynamics

- Full-bore design eliminates flow restrictions, achieving >98% volumetric efficiency.

- Flow rates: 120–500 m³/h (model-dependent).

Structural Integrity

- Pressure ratings: 35–100+ MPa for deep-well drilling 2.

- Materials: Corrosion-resistant alloys (Inconel/Hastelloy) for acidic mud environments.

Specialized Features

- Self-priming for rapid restart 1.

- Modular seats for swift maintenance.

- API 6A/7K compliance.

Mud Pump Full Open Valve High Temperature FAQs

1. What is a Mud Pump Full Open Valve High Temperature?

A Mud Pump Full Open Valve High Temperature is a specialized bonded urethane valve engineered for extreme drilling environments. Its single-piece, solid-body construction provides superior strength, making it ideal for withstanding high pressure, high temperature, and high solids conditions in oil & gas, mining, and industrial drilling operations

2. What temperature range can it withstand?

This valve is designed to excel in high-temperature environments, though specific thresholds may vary by model. It is built to handle the thermal stress of hot drilling fluids, ensuring reliable performance in hostile conditions where conventional valves may fail

3. What are its key performance features?

- High Pressure & Solids Resistance: Engineered to endure aggressive drilling scenarios with high pressure and abrasive solids.

- Long Service Life: Superior abrasion resistance and durable bonded urethane construction extend operational run time.

- Optimal Flow Dynamics: The full-open design minimizes flow restriction, enhancing pumping efficiency in heavy-duty applications

4. What industries or applications is it suitable for?

Primarily used in oil & gas drilling, mining, and construction where mud pumps operate under extreme conditions. It is particularly effective in high-temperature bonded urethane valve systems requiring robust performance

5. Are there certification or quality standards?

While specific certifications are not detailed in available data, the valve adheres to industrial standards for heavy-duty drilling components, ensuring compatibility with mud pump models like the F-1600 series

We are here to answer your questions and support your needs.