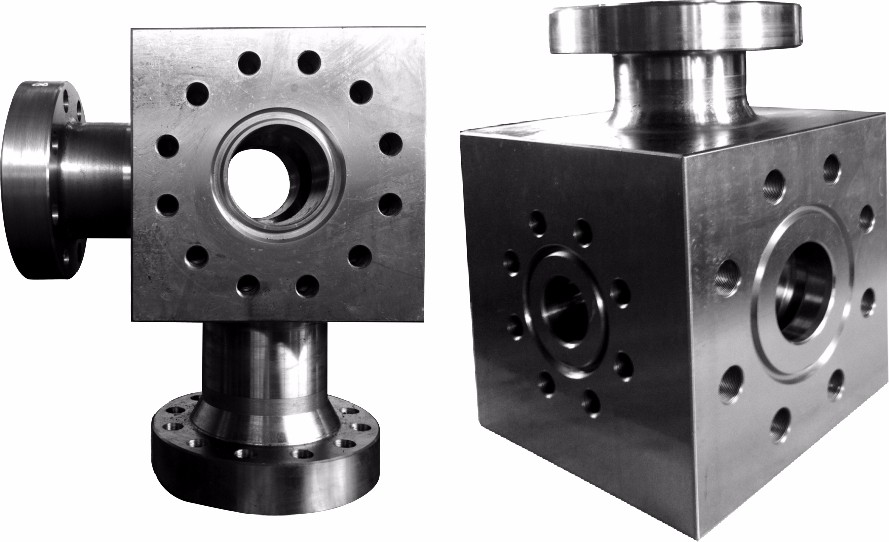

Mud Pump five way

- Fluid Flow Regulation: The five-way component acts as a central manifold, connecting critical parts such as the cylinder liner, suction valve, and discharge valve to ensure unidirectional and efficient mud flow during the pump’s operation 3.

- High-Pressure Resistance: Constructed from durable materials like high-chromium cast iron or 45# steel (similar to other fluid end parts like valve boxes and liners 3), it is engineered to withstand extreme pressure conditions typically encountered in drilling operations.

Selling Points

- High Power and Versatility

- Interchangeable Components for Reduced Costs

- Durable Materials Ensuring Longevity

- Comprehensive Spare Parts Availability

Feature

- Model: Mud Pump Five-Way

- Type: Multi-functional mud pump

- Application: Drilling, construction, maintenance, etc.

- Power Source: Electric or diesel engine (depending on model)

- Flow Rate: Variable, typically ranging from 50 to 300 gallons per minute (GPM)

- Pressure: Adjustable, usually between 100 and 500 pounds per square inch (PSI)

- Pump Head: Stainless steel or cast iron (depending on model)

- Hose Diameter: Standard sizes, such as 1″, 1.5″, or 2″ (depending on model)

- Hose Length: Customizable, typically ranging from 100 to 500 feet

- Weight: Varies by model, usually between 100 and 500 pounds

- Dimensions: Customizable, depending on specific requirements

- Materials: Stainless steel, cast iron, rubber, and other durable materials

- Certifications: CE, ISO, and other relevant certifications (depending on manufacturer)

- Warranty: Varies by manufacturer and model

- Maintenance: Regular inspection, cleaning, and lubrication recommended

- Operating Temperature: Typically between -40°C and 50°C (-40°F and 122°F)

- Storage: In a dry, cool place away from direct sunlight and moisture

- Safety Precautions: Wear appropriate personal protective equipment (PPE), follow operating instructions, and avoid using damaged equipment

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

What is a Mud Pump Five-Way?

A Mud Pump Five-Way is a multi-functional pump designed for heavy-duty applications such as drilling, construction, and maintenance. It is engineered to handle high-pressure fluid transfer, typically used in industries requiring efficient mud or slurry management

What are the key applications of this pump?

Common uses include drilling operations (oil, gas, mining), construction site dewatering, pipeline maintenance, and slurry transportation in industrial settings

What power sources are available?

The pump can be powered by either an electric motor or a diesel engine, depending on the model and operational requirements

What is the typical flow rate and pressure range?

- Flow Rate: Variable, usually 50–300 gallons per minute (GPM).

- Pressure: Adjustable, typically 100–500 pounds per square inch (PSI)

What materials are used in construction?

Key components like the pump head are made of stainless steel or cast iron for durability. Hoses and seals often use rubber or high-strength polymers

We are here to answer your questions and support your needs.