Mud Pump F1600/FB1600 fluid end module

- Valve Box Integration: Also referred to as the hydraulic cylinder, the fluid end module serves as the core part of the mud pump’s fluid end system. It features three interchangeable cylinders, allowing for easy maintenance and part replacement .

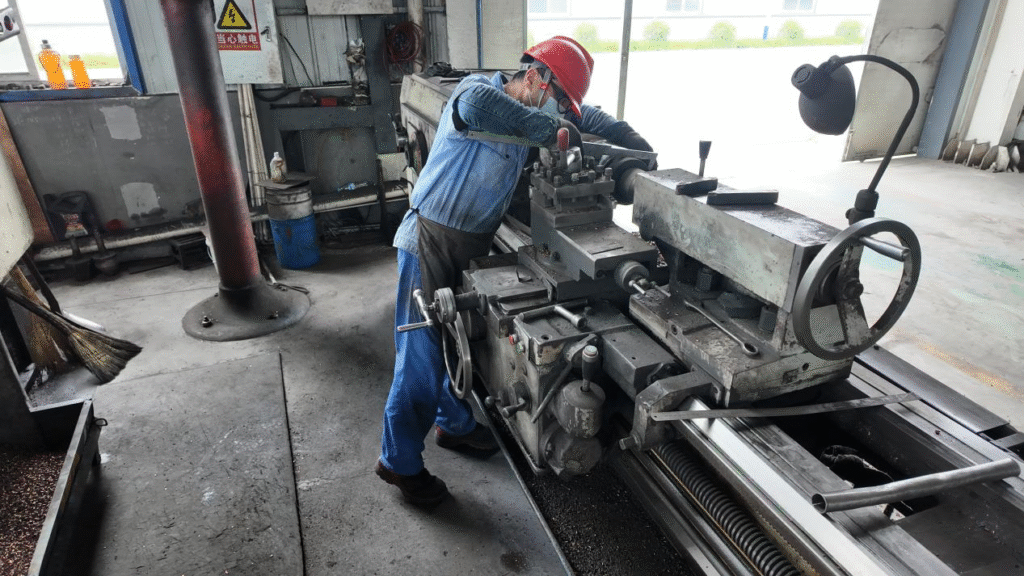

- Precision Machining: The blank is forged from high-strength alloy steel and undergoes heat treatment and multi-step processing to enhance structural integrity. Critical components such as the cylinder head’s cone sawtooth thread and screw hole curves are precision-machined to ensure leak-proof performance

Selling Points

- High Power and Versatility

- Interchangeable Components for Reduced Costs

- Durable Materials Ensuring Longevity

- Comprehensive Spare Parts Availability

Feature

🔧 Product Overview

The Fluid End Module, also known as the valve box, is responsible for directing the flow of drilling fluid (mud) through the pump system. It houses critical components such as the suction and discharge valves, cylinder liners, and pistons. The module is designed to withstand extreme pressures and abrasive conditions commonly found in drilling environments 1.

This module is specifically engineered for use with F1600 and FB1600 mud pumps, which are widely used in large-scale drilling rigs due to their high flow rates and pressure capabilities.

📐 Key Technical Specifications

Parameter Description Material High-strength alloy steel, forged and heat-treated for durability 1 Cylinder Configuration Triplex (three cylinders), fully interchangeable 1 Bore Diameter Typically matches F1600/FB1600 specifications (up to 6″ or 152mm) Working Pressure Designed for high-pressure operations, typical of 1600 hp mud pumps Thread Type Cone sawtooth thread on cylinder head for secure sealing and connection 1 Valve Design Equipped with high-performance suction and discharge valves Compatibility Suitable for F1600, FB1600, and other similar high-horsepower mud pumps 1 Surface Treatment May include chrome plating or hardening for corrosion and wear resistance Manufacturing Process Multi-channel machining processes ensure precision and longevity 1 ⚙️ Design and Functional Features

- High-Strength Construction: Made from forged alloy steel with advanced heat treatment, ensuring resistance to fatigue and stress cracking under high-pressure conditions.

- Interchangeable Cylinders: All three cylinders are interchangeable, simplifying maintenance and reducing downtime 1 .

- Precision Machining: The internal cavity and threaded connections are precision-machined to ensure leak-proof operation and optimal fluid dynamics.

- Valve Box Integration: The fluid end module includes the valve box, which houses the valves and allows for efficient fluid intake and discharge.

- Corrosion and Wear Resistance: Surface treatments such as chrome plating or nitriding enhance the lifespan of internal components exposed to abrasive drilling fluids.

🧰 Common Applications

- Oil and Gas Drilling Rigs

- Hydraulic Fracturing (Fracking) Operations

- Cementing and Acidizing Jobs

- High-Pressure Mud Circulation Systems

🔗 Related Products and Spare Parts

A complete fluid end module may include or be used with the following components:

- Cylinder liners

- Plunger pistons

- Suction and discharge valves

- Valve seats and springs

- Crossheads and piston rods

- Extension rods

These parts are often available as a maintenance kit or rebuild kit, allowing for efficient servicing and replacement of worn components 1.

✅ Advantages

- Durability: Engineered to withstand extreme pressure and abrasive conditions.

- Reliability: Precision manufacturing ensures consistent performance.

- Easy Maintenance: Interchangeable design simplifies repairs and replacements.

- Compatibility: Works seamlessly with F1600 and FB1600 mud pumps from leading manufacturers like Bomco and EMSCO.

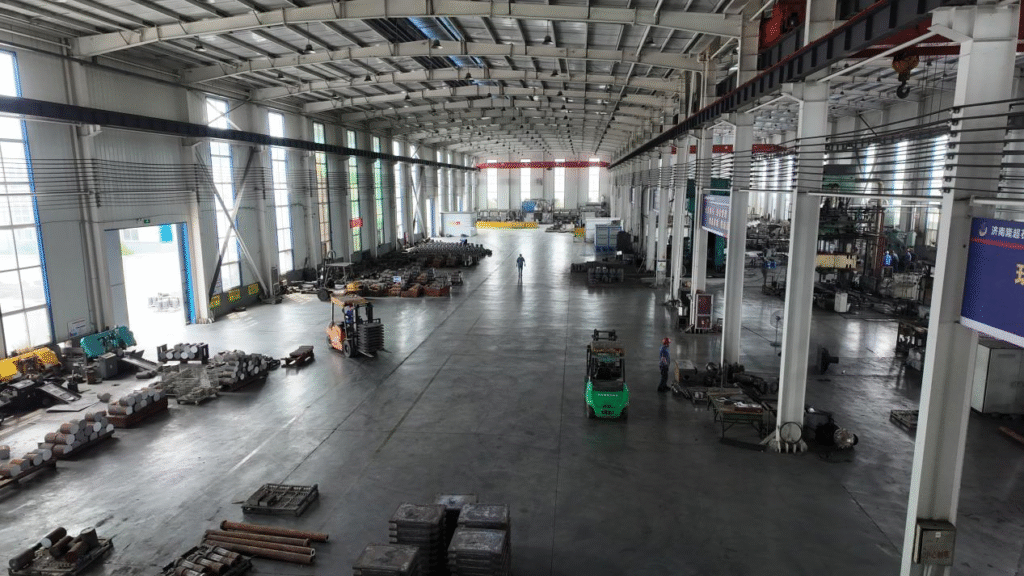

📦 Packaging and Delivery

- Packaging: Typically packed in wooden crates suitable for sea shipment.

- Delivery Time: Varies by supplier, but standard delivery is usually within 7–20 days after order confirmation 1.

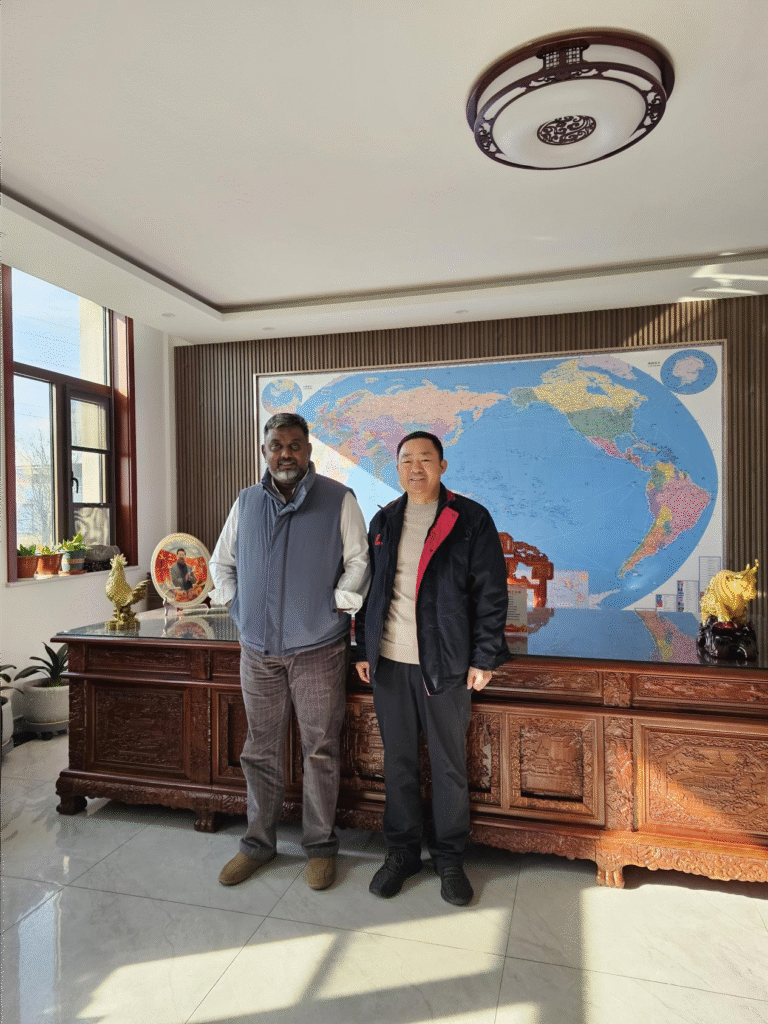

📞 Supplier Notes

Suppliers of F1600/FB1600 fluid end modules emphasize their ability to offer OEM-quality parts at competitive prices. Many companies provide custom machining services and technical support to ensure compatibility with specific pump models and field condition

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

What is the F1600/FB1600 Fluid End Module?

It is a critical component of mud pumps, also called a hydraulic cylinder or valve box, belonging to the fluid end parts. The blank is forged by high-strength alloy steel and undergoes heat treatment and multi-channel processes. The three cylinders of each pump are interchangeable

What are the key features of the F1600/FB1600 Fluid End Module?

What models is the F1600/FB1600 Fluid End Module compatible with?

It is compatible with BOMCO F1600/FA-1600/FB-1600 mud pumps, as well as other models like EMSCO F-350, F-500, F-650, F-800, F-1000, F-1300/FA-1300/FB-1300, Gardner Denver PAH, PZ series, IDECO series, etc.

What is the application of the F1600/FB1600 Fluid End Module?

It is mainly used in petroleum machinery, specifically for mud pumps in drilling rigs

How is the F1600/FB1600 Fluid End Module packaged?

The transport package is a wooden box, and the shipment method is sea shipment

We are here to answer your questions and support your needs.