Mud Pump ceramic Liner

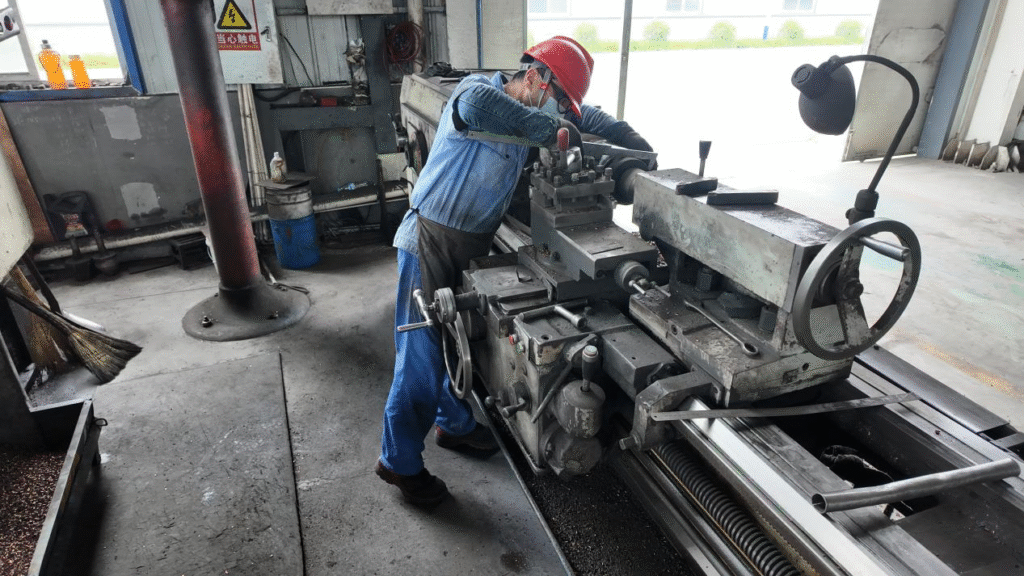

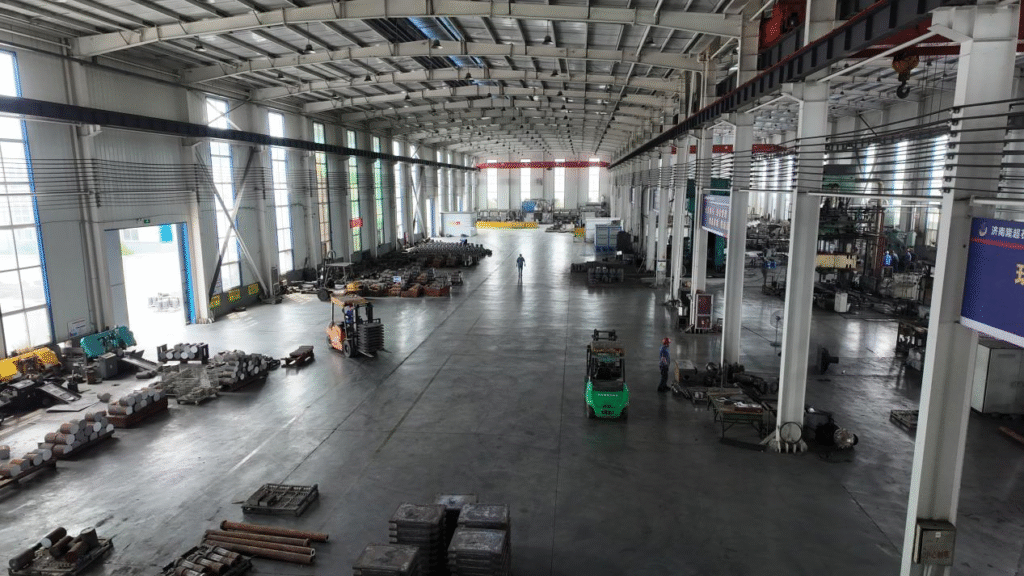

Our mud pump ceramic liner are engineered for longer service life and higher wear resistance in high-pressure drilling operations.Each liner is manufactured to meet or exceed API 7K standards, ensuring maximum service life and minimal maintenance.

Whether you’re operating in oil, gas, or geothermal drilling, our liners offer superior resistance to wear, corrosion, and extreme temperature conditions. We also support OEM/ODM customization, laser-etched branding, and flexible packaging to suit your distribution needs.

Suitable Subtitle

- Excellent wear resistance and high temperature resistance

- Excellent corrosion resistance and chemical stability

- Customized adaptation and easy installation

- Double protection of technology and brand

Suitable Subtitle

- Bore Hardness: 89-94

- Pressure rate: Up to 7,500 psi

- Temperature rate: 20-350F

- Hydrogen Sulfide: 24

Feature

- Outer Hull: #45 steel forging,HB163-217;

- Inner Sleeve: zirconia or compound ceramic material

- HP design with shoulder-on-hull to prevent inner sleeve slippage;

- Surface finish4-8 RMS

- Service Life: over 4000 hours under normal working condition,5-10 times higher than bi-metal liner;

- Operating Pressure: 7500 PSI

Parameter of ceramic inner sleeve:

Item ZTA TZP Composition Aluminum Oxide, Zirconia, Yttrium Oxide Zirconia, Yttrium Oxide Volume Density (g/cm³) ≥4.25 ≥6.00 Bending Strength (MPa) ≥580 ≥800 Fracture Toughness (MPa·m1/2) ≥9 ≥10.00 Rockwell Hardness (HRA) ≥91 ≥91 Surface Roughness (µm) ≤0.20 ≤0.20 Compressive Strength (MPa) ≥3000 ≥3000 Wear Resistance 0.20 0.20 Thermal Shock Resistance ≥450℃ ≥450℃ Zirconia Content ≥25% ≥95%

Explore Our BI-METAL LINER

| Brand | Model |

|---|---|

| BOMCO | F500, F800/1000, F1300/1600, F1600HL, F2200HL |

| EMSCO | F500, F800/1000, FB1300/1600, FC-1600, FC-2200 |

| NATIONAL | 7P50, 8P80, 9P100, 10P130, 12P160, 14P220 |

| OILWELL | A600PT, A850PT, A1100PT, A1400PT, A1700PT |

| GARDNER DENVER | PAH, PJ8, PZ7, PZ8, PZ9, PZ10, PZ11, PZ11L |

| IDECO | T500, T800, T1000, T1300, T1600 |

| DRILLMEC | 9T1000, 12T1600, 14T2200 |

| WIRTH | TPK1000, TPK1600, TPK2200 |

| RUSSIAN PUMP | 8T650, UNB600, NBT600, UNBT950, UNBT1180L |

| WEATHERFORD | MP5, MP8, MP10, MP16 |

| HONGHUA | HHF500, HHF800/1000, HHF1300/1600, HHF1600HL, 3NB-1300F/1600F |

| RONGSHENG | RSF500, RSF800/1000, RSF1300/1600 |

| RG | RGF500, RGF800/1000, RGF1300/1600 |

| LANSHI | 3NB1000C, 3NB1300C, 3NB1600 |

| QZ | 3NB800, 3NB1000, 3NB1300A, 3NB1600 |

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

Q1: What are bi-metal liners used for?

They form the cylinder chamber in a mud pump, helping generate pressure to circulate drilling fluid.

Q2: What materials do you offer?

Outer Hull: #45 steel forged, inner sleeve is for high chromium cast iron.

Q3:Which pump models are your liners compatible with?

Our liners fit popular brands like EMSCO, National, Gardner Denver, and others.

Q4: What is the lifespan of your liners?

At least 800 hours under normal working condition for bi-metal liners, even more than 1000 hours.

Q5:Do you support OEM and private labeling?

Yes, we offer full OEM services including logo engraving and customized packaging.

We are here to answer your questions and support your needs.