Our Story

Create each product with a professional attitude and professional techniques

Adhering to the motto of “Dedicated to Mud Pump Liners, Unchanged for Over 30 Years,” we are growing into a world-leading manufacturer of mud pump liners. We look forward to working with you, and our team will provide the highest quality service and products.

30

360K

Satisfied clients around the World

642

Projects have been completed in 18 countries

Our Process

Steps to Your Dream Outdoor Space

1. Consult

We begin with a personalized consultation to capture your vision and needs.

2. Design

Our experts prepare a detailed plan with all forging designs for your approval.

3. Execute

Our highly skilled team will produce all the products you purchase with precision and meticulous work.

The Goal

Our Mission

o engineer and deliver high-performance, durable mud pump components and precision-forged solutions that empower drilling operations worldwide. We leverage advanced manufacturing technologies and rigorous quality control to ensure reliability in extreme conditions, reducing downtime and maximizing efficiency for our global clients in the energy and industrial sectors.

The Outlook

Our Vission

To pioneer the future of mud pump innovation and forging excellence, becoming the most trusted global partner for mission-critical drilling components. We will achieve this by:

1. Advancing Technology – Continuously innovating in materials science and forging processes (e.g., patented railway bridge bearing plate equipment .

3. Setting Industry Standards – Leading in sustainability, precision, and customer-centric solutions for the oil, gas, and heavy machinery sectors.

Giving Back

Celebrating Innovation in Forged Mud Pump Solutions

Industry Engagement & Feedback

Global Connections: Engaged with drilling contractors, OEMs, and engineers from 15+ countries, addressing critical needs like:

▶️ Abrasion resistance in deep-well projects.

▶️ Supply chain reliability for emergency replacements.

– Technical Dialogues: Live demonstrations of our closed-die forging process sparked discussions on metallurgical innovations, with particular interest in our non-destructive testing (NDT) protocols for zero-defect assurance.

Key Takeaways & Future Commitments

The overwhelming response reaffirms our mission: To engineer forged components that eliminate downtime. Moving forward, we commit to:

🔧 Expanding R&D: Developing nano-coated valves for corrosive mud environments (Q1 2026 launch).

🌍 Strengthening Global Logistics: Reducing lead times for Asia-Pacific and MENA regions.

🤝 Deepening Partnerships: Collaborating with drilling firms on predictive maintenance solutions.

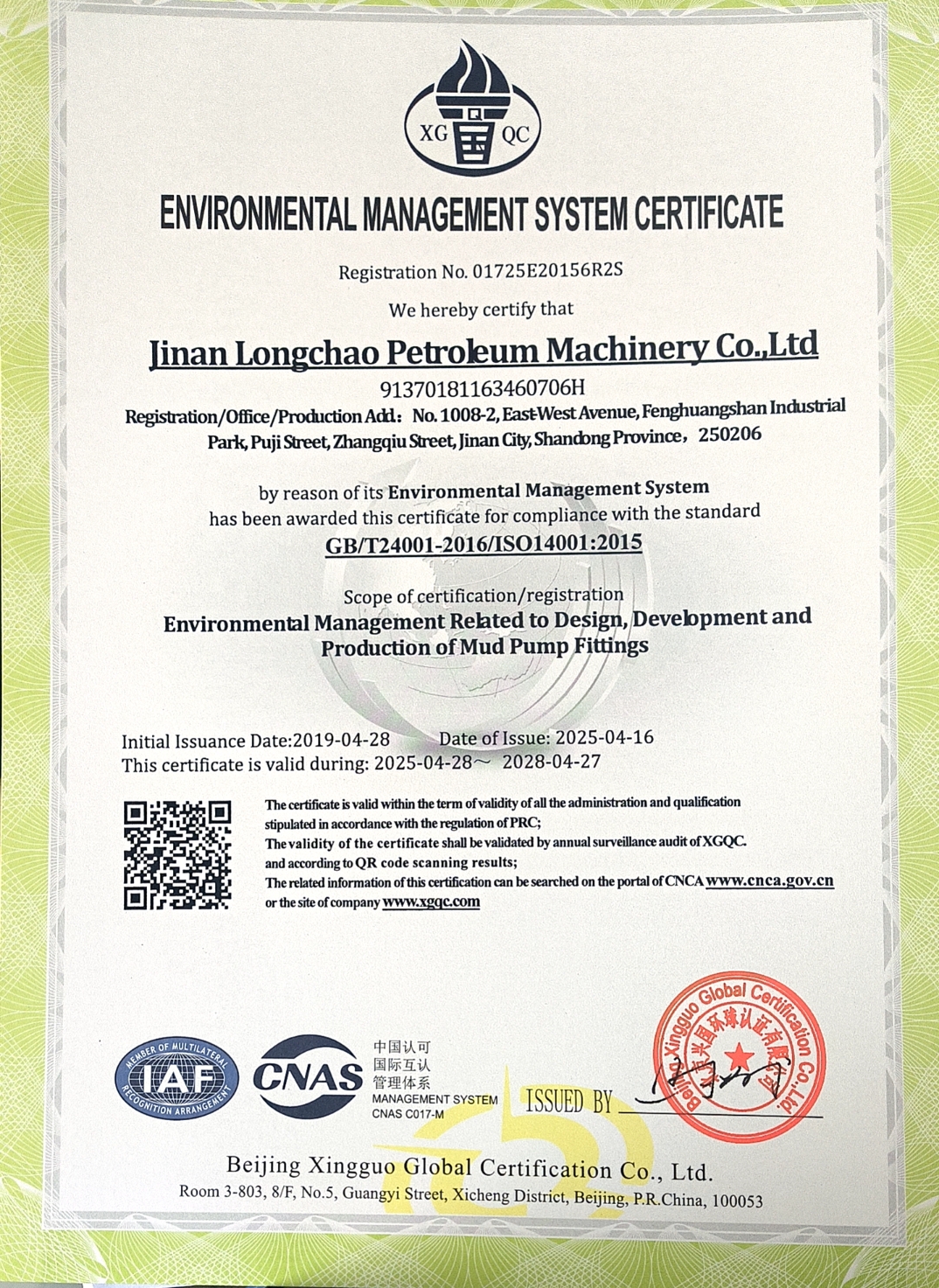

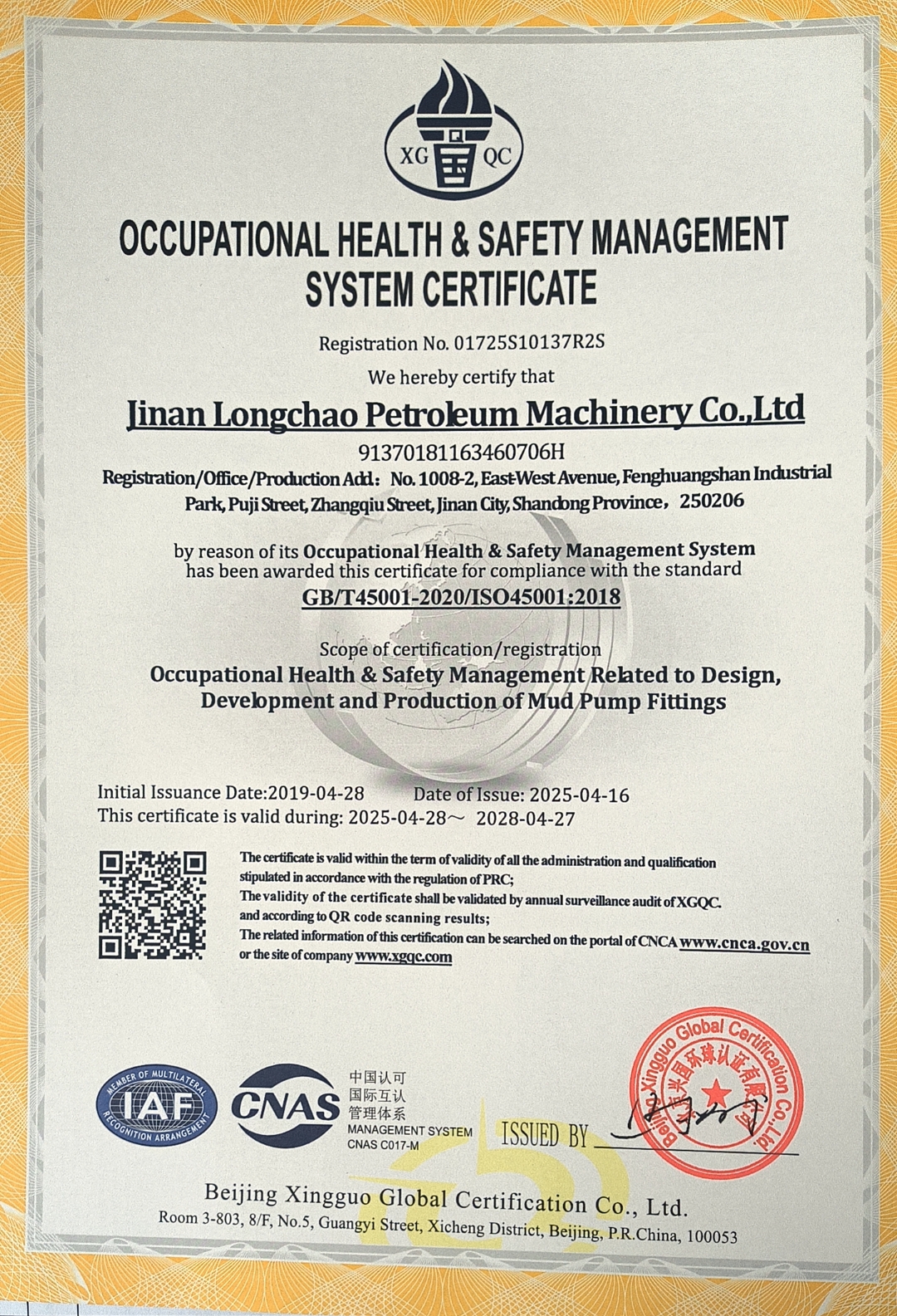

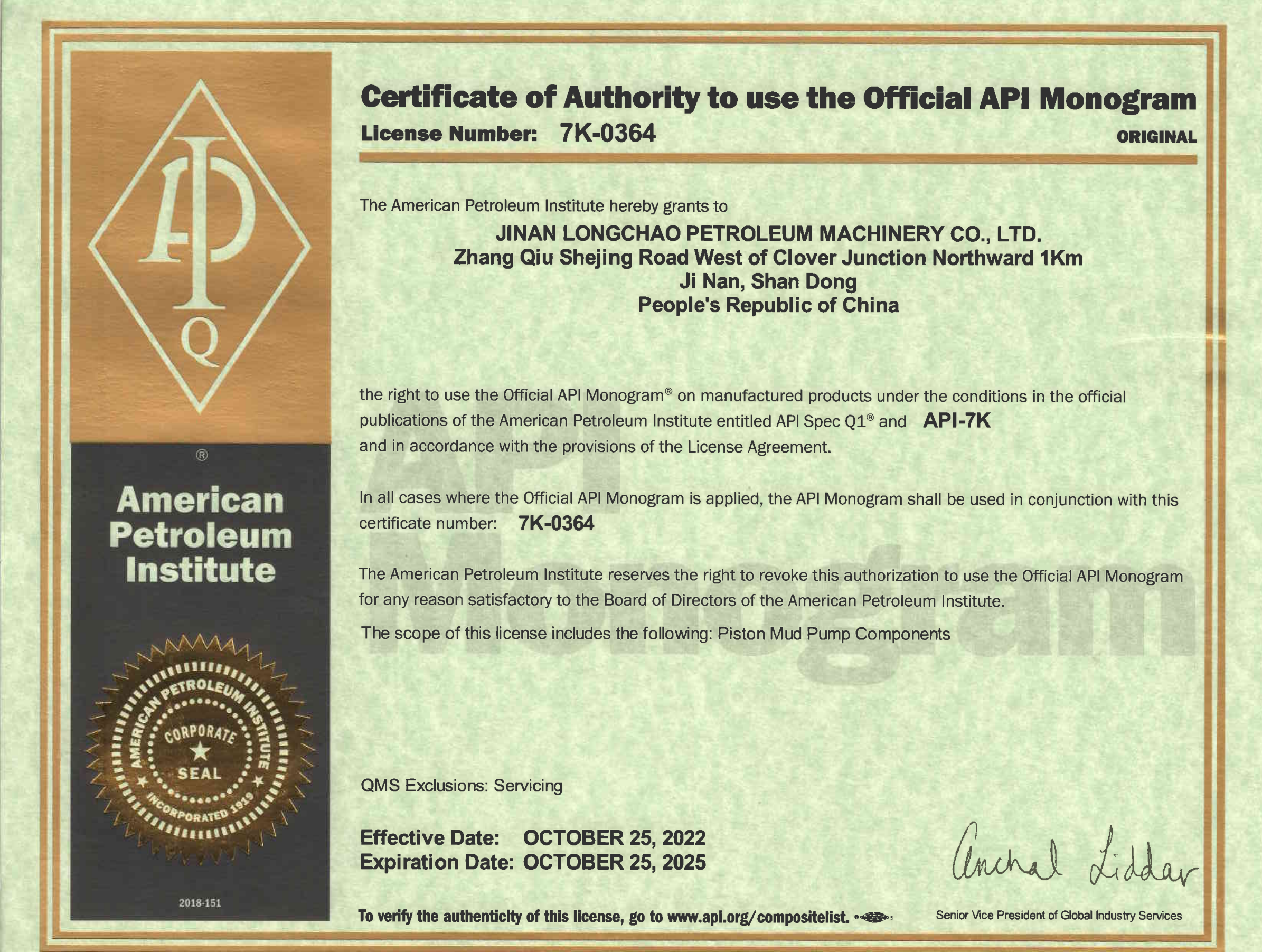

Certified Excellence in Quality and Safety

Longchao Petroleum Machinery is proud to be ISO 9001 and ISO 45001 certified, ensuring strict compliance with international quality management and occupational health & safety standards. Our certifications guarantee superior product performance and outstanding operational integrity.

We are here to answer your questions and support your needs.