Mud Pump Bull nose extreme piston

Built for extreme durability, RedRock HT urethane pistons redefine reliability in mud pump performance. Redefining efficiency and endurance, these high-performance liners offer superior resistance to wear, corrosion, and thermal stress—ensuring maximum longevity in the most demanding drilling environments.

Our pistons are designed with meticulous attention to detail, providing a perfect fit and smooth operation every time, making our HT urethane bonded pistons the best choice for operations that demand uncompromising performance.

Selling Points

- Enhanced Structural Integrity

- Superior Sealing Performance

- Abrasion and Corrosion Resistance

- Cost-Effective Maintenance

Basic parameters

- Preassure rate: 7,500 psi

- Temperature rate: 350F

- Suitable for: Oil, Synthetic and Water Muds

Feature

Key Details and Features

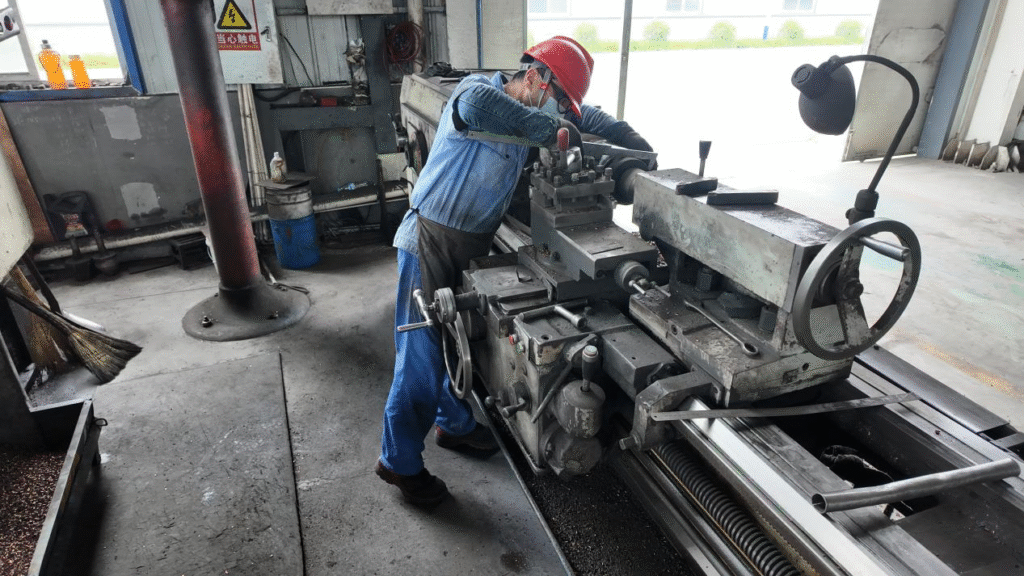

- Application: Primarily used in heavy-duty mud pumps for oilfield drilling, mining, and construction projects, where resistance to abrasion and high pressure is critical.

- Design Advantages: The bull nose shape minimizes fluid turbulence, reduces friction between the piston and cylinder liner, and enhances sealing performance to prevent fluid leakage.

- Material Composition: Typically constructed from high-strength rubber compounds (e.g., nitrile rubber, polyurethane, or ethylene propylene diene monomer (EPDM)), often reinforced with fabric or metal cores for added structural integrity.

- Replaceable Design: Like standard rubber pistons, the bull nose extreme piston features a replaceable structure, allowing for quick maintenance and replacement to minimize downtime during drilling operations.

Technical Parameters (Typical Specifications)

Parameter Description Pump Compatibility Compatible with triplex or duplex mud pumps (e.g., models from Gardner Denver, National Oilwell Varco, or Emsco). Nominal Diameter Common sizes range from 3.5 inches (89 mm) to 8 inches (203 mm), depending on pump model and application. Operating Pressure Rating Designed to withstand pressures up to 5,000–15,000 psi (34.5–103.4 MPa), depending on material and construction. Temperature Range -40°C to 120°C (-40°F to 248°F), suitable for extreme downhole or surface temperature conditions. Certifications May comply with industry standards such as API 7K (American Petroleum Institute) for oilfield equipment. Performance Characteristics

- Abrasion Resistance: Formulated to resist wear from sand, gravel, and other abrasive particles in drilling mud.

- Flexibility: Maintains elasticity under high pressure to ensure consistent sealing and prevent deformation.

- Service Life: Extended operational life compared to standard pistons, thanks to advanced materials and optimized design, reducing replacement frequency.

Mud Pump Bull Nose Extreme Piston FAQs

1. What is a Mud Pump Bull Nose Extreme Piston?

A Bull Nose Extreme Piston is a specialized high-performance piston designed for mud pumps in demanding drilling environments (e.g., oil, gas, or mining). Its “bull nose” shape refers to the rounded, tapered front end, which optimizes fluid flow dynamics and reduces wear. This piston is engineered to withstand extreme pressure, abrasion, and high temperatures, making it suitable for heavy-duty operations like deep-well drilling or high-viscosity mud applications.

2. What Materials Are Used in Its Construction?

While specific materials are not detailed in the provided search results, mud pump pistons typically use robust materials to handle harsh conditions. Common options include:

- High-grade rubber (e.g., nitrile, polyurethane) for flexibility and wear resistance.

- Reinforced composites or metal cores (e.g., steel) for structural integrity under high pressure.

- Bonded urethane/rubber combinations (similar to standard replaceable pistons) to balance durability and sealing performance

3. What Are the Key Advantages Over Standard Pistons?

- Enhanced Durability: The “bull nose” design minimizes stress concentrations, reducing premature failure from abrasion or impact.

- Improved Fluid Dynamics: The rounded profile reduces turbulence during mud displacement, optimizing pump efficiency and reducing energy loss.

- Extended Service Life: Engineered for extreme conditions, it may outlast standard pistons in high-pressure (e.g., >30 MPa) or abrasive mud environments.

4. How Does It Fit Into Mud Pump Assembly?

Like standard pistons, the Bull Nose Extreme Piston is part of the reciprocating mechanism:

- It connects to the pump’s piston rod and moves within the cylinder liner.

- Sealing &间隙 (Clearance): Critical for performance. For reference, standard pistons require precise assembly gaps (e.g., 0.08–0.16 mm between piston and cylinder liner) to prevent leakage or jamming 1. The Bull Nose design may have similar or tighter tolerances for extreme conditions.

5. What Maintenance is Required?

- Regular Inspection: Check for wear, cracks, or deformation in the rubber/urethane surface, especially after prolonged use in abrasive mud.

- Clearance Checks: Ensure piston-to-cylinder liner间隙 remains within specified limits to avoid friction-induced overheating or leakage 1.

- Replacement Intervals: Depends on operating conditions (e.g., mud viscosity, pressure). In extreme environments, replace before visible wear compromises sealing.

We are here to answer your questions and support your needs.