Mud Pump Urethane bond piston

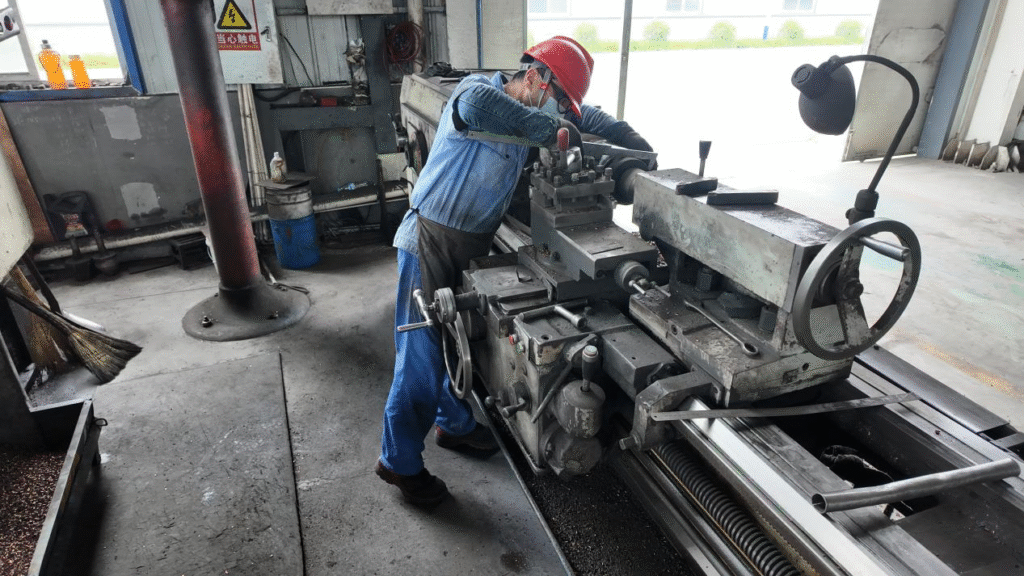

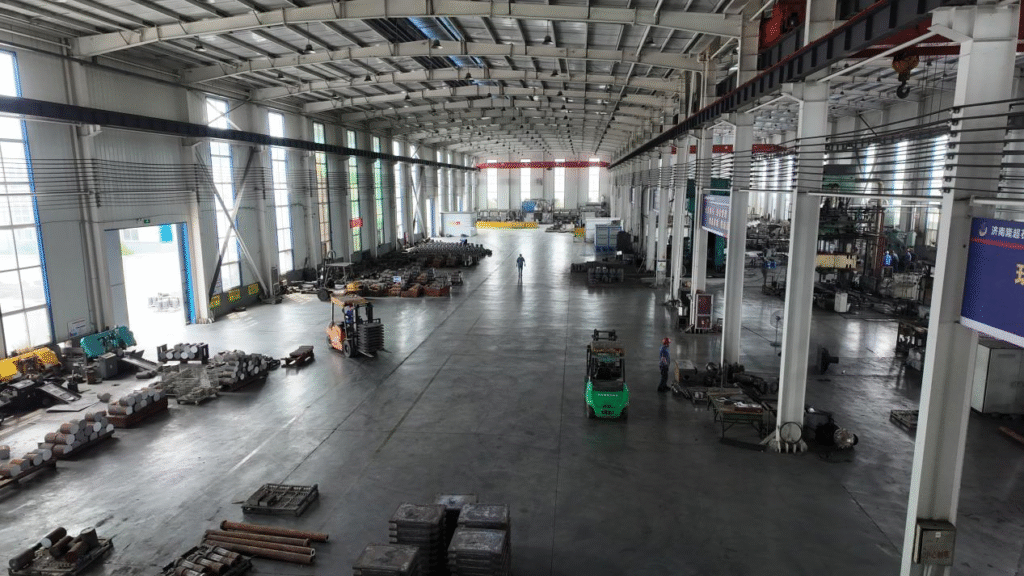

Crafted with the highest standards, our rubber bonded pistons are manufactured using premium materials and cutting-edge technology. This ensures that each liner is robust, reliable, and built to last in the most demanding drilling environments.

Our pistons are designed with meticulous attention to detail, providing a perfect fit and smooth operation every time, making our rubber bonded pistons the best choice for operations that demand uncompromising performance.

Selling Points

- Enhanced Structural Integrity

- Superior Sealing Performance

- Abrasion and Corrosion Resistance

- Cost-Effective Maintenance

Basic parameters

- Preassure rate: 5,000 psi

- emperature rate: 180F

- Suitable for: Water/Synthetic based mud

Feature

- Application: Used in mud pumps for oil and gas drilling operations.

- Material: Urethane

- Bonding: Bonded to the piston rod for improved structural integrity

- Certifications:

- API (American Petroleum Institute)

- ISO

- Warranty: 1-year warranty (subject to manufacturer’s terms and conditions)

Technical Parameters

| Parameter | Details |

|---|---|

| Pump Model | Triplex mud pumps, such as GARDENER DAVER, F/T/3NB/PZ Series, etc. |

| Piston Size | Various sizes available, e.g., 3-1/2, 4-1/2, 5-1/2, 6-1/2 inches |

| Certification | API |

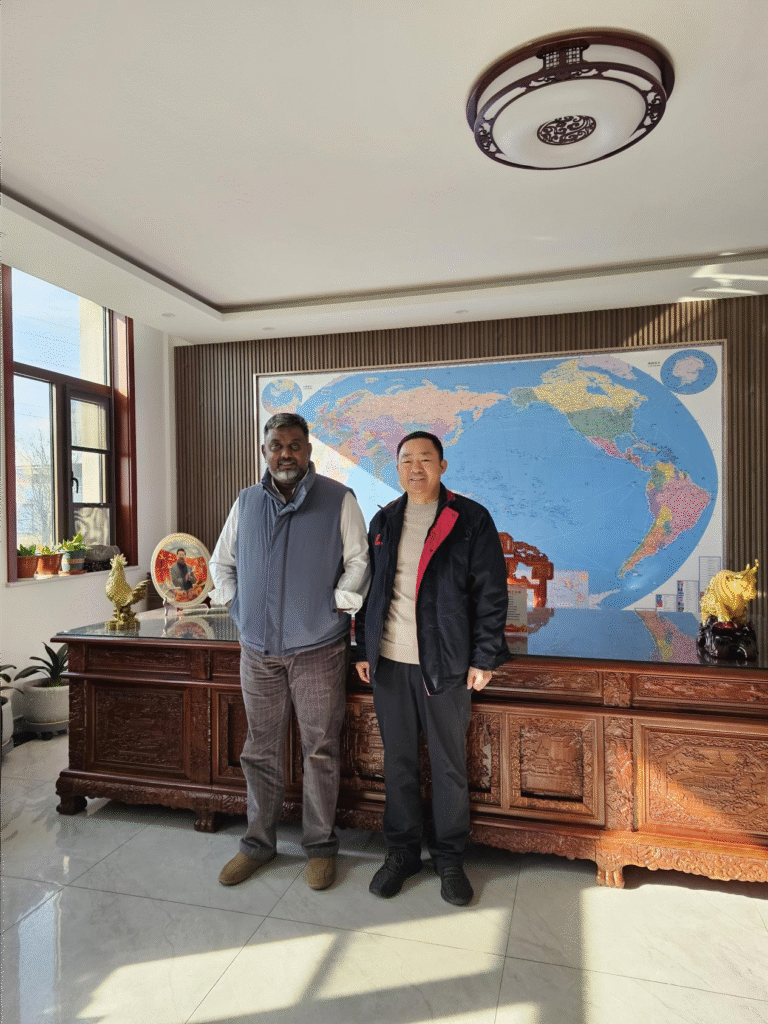

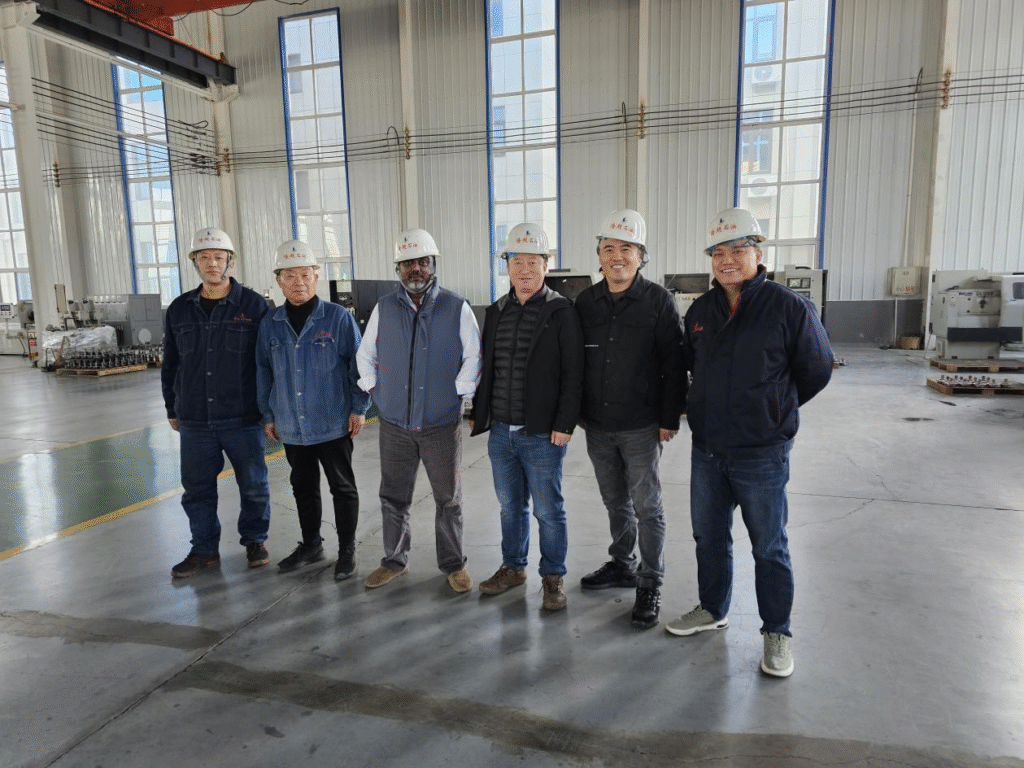

| Supplier Information | lc has 10 years of experience in the petroleum equipment industry, with overseas companies in the United States, Russia, and other countries. |

Outer Hull: #45 steel forging,HB163-217;

Inner Sleeve: high chromium cast iron centrifugal casting, HRC≥60;

HP lip design to prevent inner sleeve slippage;

Surface finish for inner sleeve Ra0.05, much higher than API standard Ra0.2;

Service Life: not less than 800 hours under normal working condition;

High Chromium Content: 26%-28%

Operating Pressure: 7500 PSI

Chemical Composition of Outer Hull:

ChemicalComposition | C | Mn | Si | P | S | Cr |

Content (%) | 0.42-0.50 | 0.5-0.8 | 0.17-0.37 | <0.06 | <0.05 | <0.25 |

Chemical Composition of Inner Sleeve:

C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

2.80-3.10 | 0.5-1.0 | 0.50-0.80 | ≤0.10 | ≤0.06 | 26-28 | 0-1.0 | 0-1.5 | 0-2.0 |

Mud Pump Urethane bond piston FAQ

1. What is a Urethane Bonded Piston for Mud Pumps?

A urethane bonded piston is a critical component in mud pumps, designed with a urethane rubber layer bonded to a metal or composite core. This structure combines the elasticity of urethane with the structural support of the core, ensuring efficient reciprocating motion to transfer drilling fluid (mud) in oil and gas drilling operations. The bonded design enhances durability and resistance to abrasion, pressure, and chemical degradation from drilling fluids.

2. What Advantages Does Urethane Offer Over Other Materials?

- Abrasion Resistance: Urethane exhibits superior wear resistance compared to natural rubber, extending piston lifespan in harsh drilling environments.

- Flexibility & Elasticity: Maintains shape and performance under high pressure and temperature fluctuations, reducing leakage risks.

- Chemical Compatibility: Resists degradation from hydrocarbons, acids, and drilling fluid additives common in oilfield operations.

- Bond Strength: The bonded construction ensures strong adhesion between the urethane layer and core, preventing delamination during operation.

3. How Do I Select the Right Urethane Bonded Piston for My Mud Pump?

Consider the following factors:

- Pump Model: Match piston dimensions (diameter, length) to the pump’s cylinder specifications (e.g., triplex or duplex pumps).

- Operating Conditions: Pressure rating, fluid type (water-based vs. oil-based mud), and temperature range influence urethane hardness (durometer) selection.

- API Certification: Ensure compliance with API 7K standards for oilfield equipment safety and performance.

4. What Maintenance Practices Maximize Piston Lifespan?

- Regular Inspection: Check for cracks, urethane wear, or core corrosion before each use.

- Proper Installation: Ensure alignment with the cylinder to avoid uneven wear; torque bolts to manufacturer specifications.

- Fluid Cleanliness: Remove debris from drilling fluid to minimize abrasive damage to the urethane surface.

- Storage: Store pistons in a cool, dry environment away from direct sunlight and chemicals to prevent material degradation.

5. When Should a Urethane Bonded Piston Be Replaced? Replace pistons if:

Replace pistons if:

- Urethane layer shows significant wear (e.g., thinning, cracks, or loss of elasticity).

- Leakage occurs around the piston during operation.

- Core material is corroded or damaged, compromising structural integrity.

- Performance declines (e.g., reduced pump efficiency or pressure loss).

We are here to answer your questions and support your needs.