Mud Pump Full Open Valve

Discover the power of our valve assemblies engineered to conquer the toughest drilling environments. Redefining efficiency and endurance.

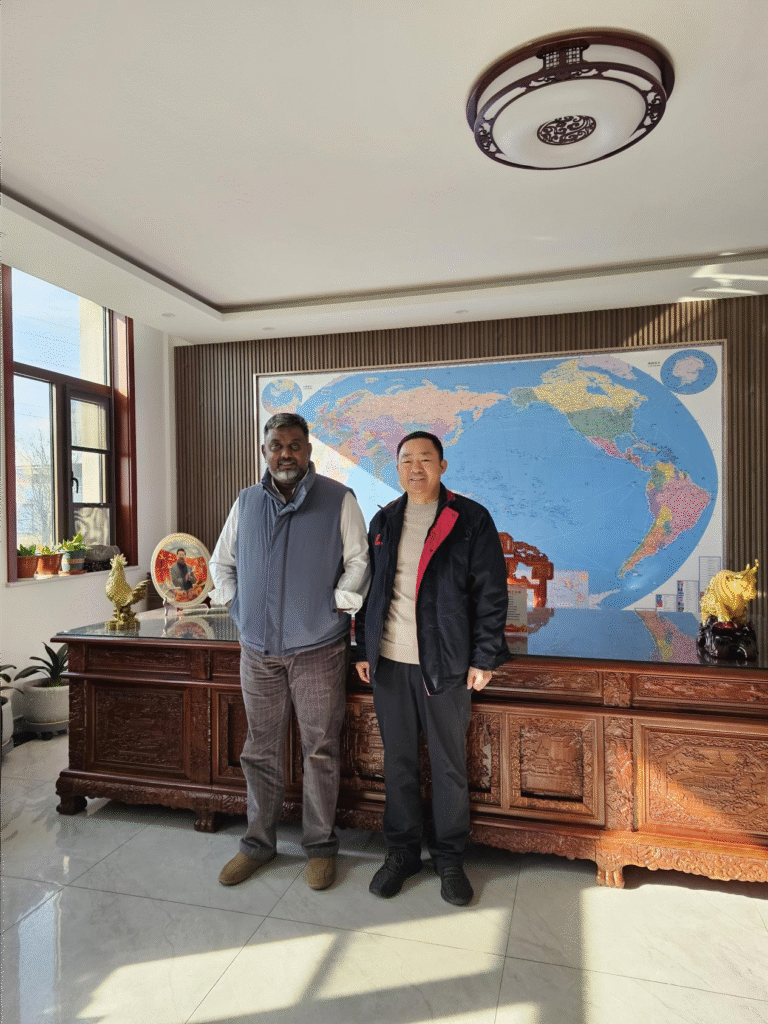

Designed to withstand extreme pressures and abrasive conditions, our high-performance valve assemblies

ensure consistent, reliable operation, day in and day out. Whether you’re tackling deep wells or demanding

terrains, trust LC Mud Pumps to keep your mud pumps running stronger and longer.

Selling Points

- Excellent resistance to extreme environments

- High-strength structure and reliability design

- Efficient adaptability and compatibility

- Easy maintenance and cost optimization

performance

- Preassure rate: 7500 psi (seat)

- Temperature rate: 180°F (Std Insert)

- Bore Hardness: Water and synthetic- based

- API sizes: 6-1/4" to 7-1/2"

Feature

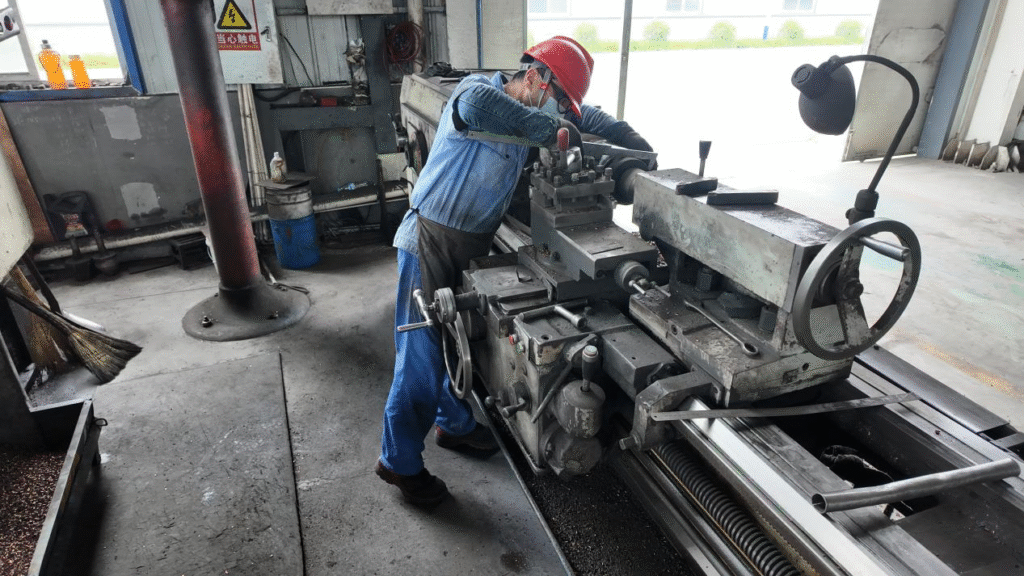

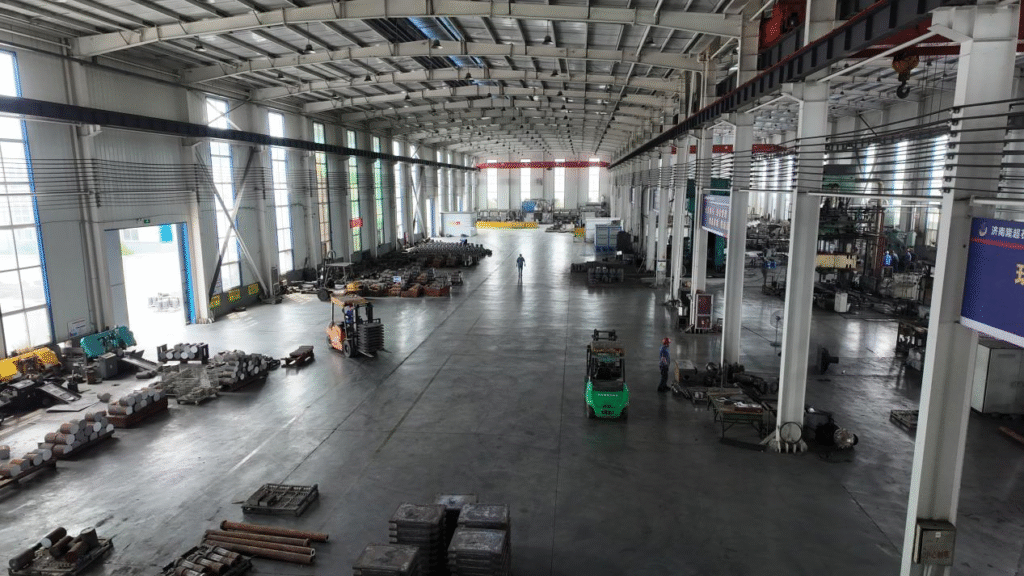

The Mud Pump Full Open Valve is a specialized component for mud circulating systems in oil & gas drilling, mining, and construction industries. It is engineered to handle high-pressure, high-temperature (HPHT), and high-solids environments, ensuring efficient mud pumping and circulation. Key features include a one-piece solid-body construction, API-7K compliance, and compatibility with major mud pump models .

Core Technical Specifications

Parameter Details Pressure Rating 5,000–7,500 psi (34.5–51.7 MPa) Temperature Range -20°C to 200°C; high-temperature versions available Materials Forged steel valve body, 20CrMnTi valve stem, stainless steel valve seat, bonded urethane inserts Design Features Full-open flow path, 3-Web center-guided system, oxide-coated corrosion resistance Compliance API-7K standards, interchangeable with OEM parts Structural Advantages for Enhanced Performance

- One-Piece Solid-Body Construction: Provides superior rigidity and strength to withstand extreme pressure and prevent deformation during high-pressure drilling operations .

- Optimized Flow Dynamics: The full-open design minimizes flow resistance, improving mud circulation efficiency and reducing energy loss compared to standard valves .

- Replaceable Components: Features snap-in inserts (standard/high-temperature options) and modular valve seats for quick maintenance, reducing downtime .

Application Scenarios

- Primary Use: Oil & gas drilling mud pumps (e.g., F-1600 series, Mission Part 9700250) .

- Industrial Extensions: Mining slurry pumps, construction mud circulation systems, and high-pressure fluid transfer in harsh environments.

Key Performance Benefits

- Long Service Life: High-abrasion-resistant materials (urethane inserts, 20CrMnTi steel) and corrosion-resistant coatings extend operational durability .

- Reliability in Hostile Conditions: Engineered to handle high solids content, HPHT environments, and rapid pressure fluctuations without performance degradation .

- Cost Efficiency: Interchangeable parts and low-maintenance design lower lifecycle costs for drilling operations .

This product integrates robust materials, precision engineering, and user-centric design to deliver consistent performance in the most demanding industrial applications.

Global Models of Mud Pump Full Open Valve

| Model Number | Valve Type | Key Specifications | Compatibility | Material | Pressure Range | Temperature Range |

|---|---|---|---|---|---|---|

| FB-1600 | Full Open Valve | Single-piece solid-body construction for high-pressure drilling; excellent abrasion resistance; optimized for hostile environments with high solids. | OILWELL A series (e.g., A-560-PT, A-850/1100-PT); mud pumps in oil/gas drilling. | Forged steel body with bonded urethane inserts | 5,000–7,500 psi (34.5–51.7 MPa) | -20°C to 200°C |

| F-1600 Heavy Duty | Heavy Duty Valve | Bonded urethane design for high-pressure, high-temperature, and high-solids resistance; superior performance and long service life; reduces wear in abrasive media. | General slurry pumps for mining, construction, and drilling applications. | Bonded urethane with stainless steel components | High pressure (implied from context; not explicitly stated) | Standard and high-temperature versions available |

| F-1600 Double Angle | Double Angle Valve (3-Web System) | Replaceable snap-in insert for easy maintenance; oxide-coated for corrosion resistance during storage; center-guided valve system for stability. | API-7K standard; compatible with various mud pumps like BWY series. | Stainless steel valve stem and seat with coated body | Not specified | -20°C to 200°C |

Notes:

- Source Reliance: All information is based on 1, which provides comprehensive details on these valves, including applications in oil/gas drilling, mining, and construction. Models like FB-1600 are emphasized as high-performance options for extreme conditions.

- Completeness: This list focuses on the most documented models from the search results. For a full range of global models (e.g., additional variants or OEM-specific types), visit the product page1.

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

1. What is the primary function of a Mud Pump Full Open Valve in drilling operations?

The Mud Pump Full Open Valve is a critical component in mud circulating systems, designed to control the flow of high-pressure mud during drilling. Its full-open design maximizes flow area, minimizing pressure drop and ensuring efficient mud circulation in harsh environments like oil&gas drilling, mining, and construction

2. What materials are used in manufacturing Mud Pump Full Open Valves, and how do they enhance performance?

Key materials include 20CrMnTi alloy steel (for valve stems), forged steel (valve body), stainless steel (valve seats), and high-temperature bonded urethane (sealing inserts). These materials provide superior abrasion resistance, high-pressure tolerance (5,000–7,500 psi/34.5–51.7 MPa), and corrosion protection, ensuring durability in high-solids and extreme temperature (-20°C to 200°C) conditions

3. How does the Full Open Valve design differ from standard mud pump valves, and what advantages does it offer?

Unlike conventional valves, the Full Open Valve features a single-piece solid-body construction and optimized flow path, which reduces turbulence and pressure loss. This design enhances rigidity for high-pressure operations and improves mud flow efficiency, leading to longer run life and reduced maintenance downtime compared to multi-component valves

4. Are Mud Pump Full Open Valves compatible with API standards and common mud pump models?

Yes, most Full Open Valves comply with API specifications (e.g., API seat standards) and are interchangeable with OEM parts. They are compatible with popular mud pump models, including F-1600 series, Mission Part 9700250, and other heavy-duty pumps used in oil&gas and mining industries

5. What maintenance practices are recommended to extend the service life of a Full Open Valve?

Recommended practices include:

- Regular inspection of urethane inserts for wear or damage;

- Cleaning and oxide coating treatment during storage to prevent corrosion;

- Using compatible API seats for proper sealing;

- Replacing snap-in inserts (available in standard/high-temperature versions) instead of full valve assembly when applicable

We are here to answer your questions and support your needs.