Mud Pump Bimetallic cylinder liner

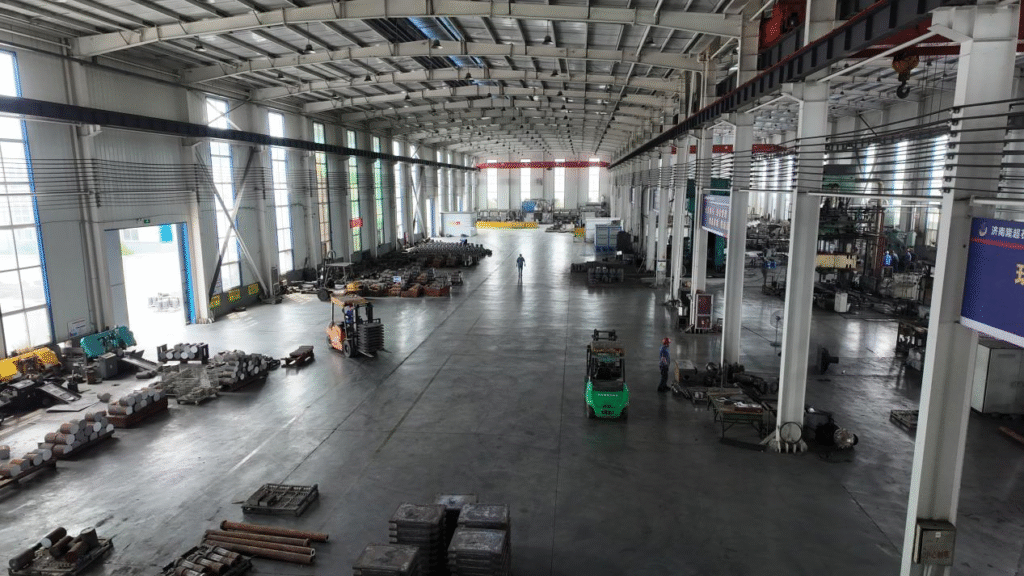

Our bi-metal liners are engineered for durability, precision, and performance in high-pressure drilling operations.Each liner is manufactured to meet or exceed API 7K standards, ensuring maximum service life and minimal maintenance.

Selling Points

- Wear and corrosion resistant

- The equipment has a long service life

- Wide range of application scenarios and adaptability

- Double protection of technology and brand

Suitable Subtitle

- Bore Hardness: 60-67

- Pressure rate: Up to 7,500 psi

- Temperature rate: 20-240F

- Hydrogen Sulfide: 22

Feature

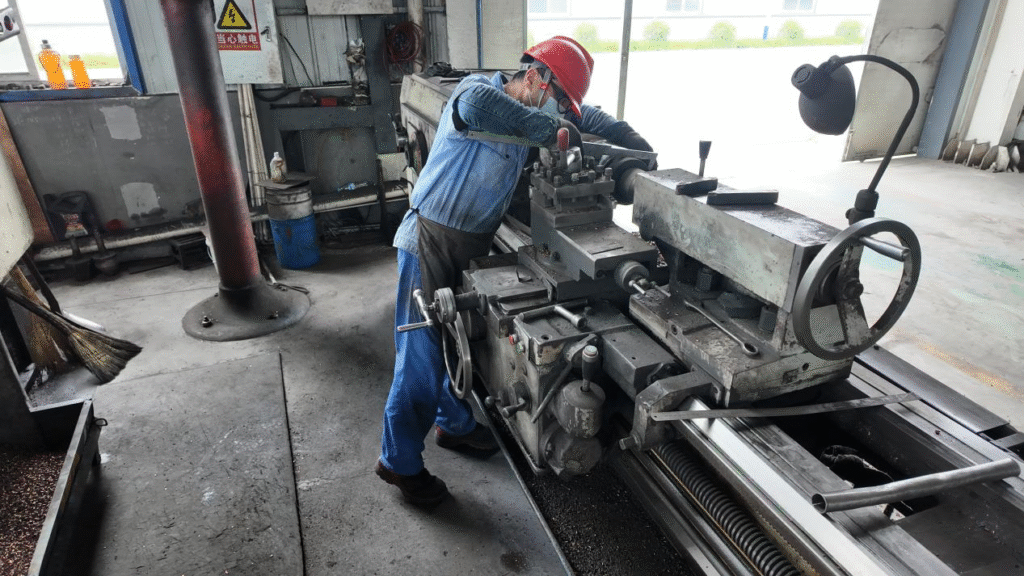

Outer Hull: #45 steel forging,HB163-217;

Inner Sleeve: high chromium cast iron centrifugal casting, HRC≥60;

HP lip design to prevent inner sleeve slippage;

Surface finish for inner sleeve Ra0.05, much higher than API standard Ra0.2;

Service Life: not less than 800 hours under normal working condition;

High Chromium Content: 26%-28%

Operating Pressure: 7500 PSI

Chemical Composition of Outer Hull:

ChemicalComposition | C | Mn | Si | P | S | Cr |

Content (%) | 0.42-0.50 | 0.5-0.8 | 0.17-0.37 | <0.06 | <0.05 | <0.25 |

Chemical Composition of Inner Sleeve:

C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

2.80-3.10 | 0.5-1.0 | 0.50-0.80 | ≤0.10 | ≤0.06 | 26-28 | 0-1.0 | 0-1.5 | 0-2.0 |

Explore Our BI-METAL LINER

| Brand | Model |

|---|---|

| BOMCO | F500, F800/1000, F1300/1600, F1600HL, F2200HL |

| EMSCO | F500, F800/1000, FB1300/1600, FC-1600, FC-2200 |

| NATIONAL | 7P50, 8P80, 9P100, 10P130, 12P160, 14P220 |

| OILWELL | A600PT, A850PT, A1100PT, A1400PT, A1700PT |

| GARDNER DENVER | PAH, PJ8, PZ7, PZ8, PZ9, PZ10, PZ11, PZ11L |

| IDECO | T500, T800, T1000, T1300, T1600 |

| DRILLMEC | 9T1000, 12T1600, 14T2200 |

| WIRTH | TPK1000, TPK1600, TPK2200 |

| RUSSIAN PUMP | 8T650, UNB600, NBT600, UNBT950, UNBT1180L |

| WEATHERFORD | MP5, MP8, MP10, MP16 |

| HONGHUA | HHF500, HHF800/1000, HHF1300/1600, HHF1600HL, 3NB-1300F/1600F |

| RONGSHENG | RSF500, RSF800/1000, RSF1300/1600 |

| RG | RGF500, RGF800/1000, RGF1300/1600 |

| LANSHI | 3NB1000C, 3NB1300C, 3NB1600 |

| QZ | 3NB800, 3NB1000, 3NB1300A, 3NB1600 |

BI-METAL LINER & Seat & Spare Parts – Buyer FAQs

Q1: What are bi-metal liners used for?

They form the cylinder chamber in a mud pump, helping generate pressure to circulate drilling fluid.

Q2: What materials do you offer?

Outer Hull: #45 steel forged, inner sleeve is for high chromium cast iron.

Q3:Which pump models are your liners compatible with?

Our liners fit popular brands like EMSCO, National, Gardner Denver, and others.

Q4: What is the lifespan of your liners?

At least 800 hours under normal working condition for bi-metal liners, even more than 1000 hours.

Q5:Do you support OEM and private labeling?

Yes, we offer full OEM services including logo engraving and customized packaging.

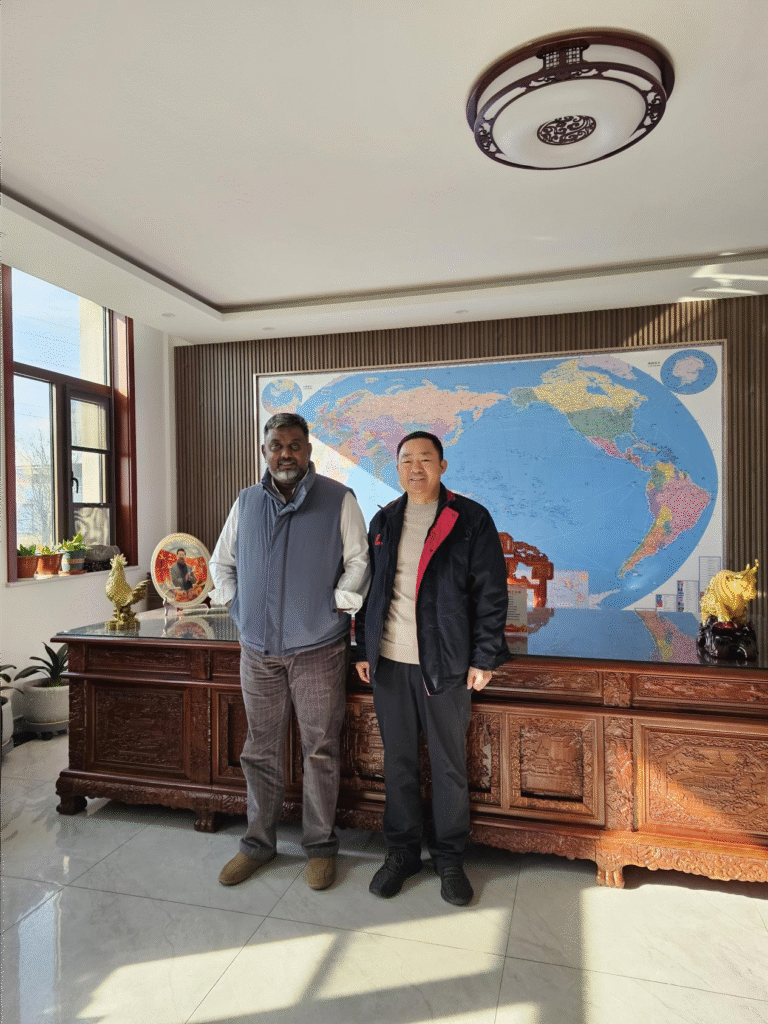

Get in Touch With Us

We are here to answer your questions and support your needs.