Our Services

From Innovative Design to Meticulous Maintenance, We Deliver Exceptional Results Tailored to your vision.

MUD PUMP PARTS

Product delivery process/OEM

Full-Chain Intelligent Manufacturing of Mud Pump Parts: A Six-Step Closed Loop from Precise Requirements to Zero-Defect Delivery

1.Intelligent Demand Anchoring

Based on the operating parameter matrix (solids content/pH value/particle hardness, etc.) and analysis of the failure patterns of existing parts, a customized demand profile is generated to eliminate adaptation errors.

2.Digital Twin Solution

CAE simulation previews component life: Dynamic optimization of valve seat stress distribution (control ≤70MPa), and material laboratory benchmarking against international wear resistance standards (GB/T 25999-2010).

4.Flexible Intelligent Manufacturing Execution

Modular production lines can cope with urgent orders: manual ancient cladding + five-axis precision grinding (surface roughness Ra 0.4μm), increasing emergency production capacity by 40%.

3.Six-Dimensional Holographic Testing

Three rigorous standards for material quality (Cr element deviation ≤0.3%), form and position tolerance (cylindricity of cylinder liner ≤0.02mm), and pulse fatigue (≥500,000 cycles), with RFID chip embedded for traceability.

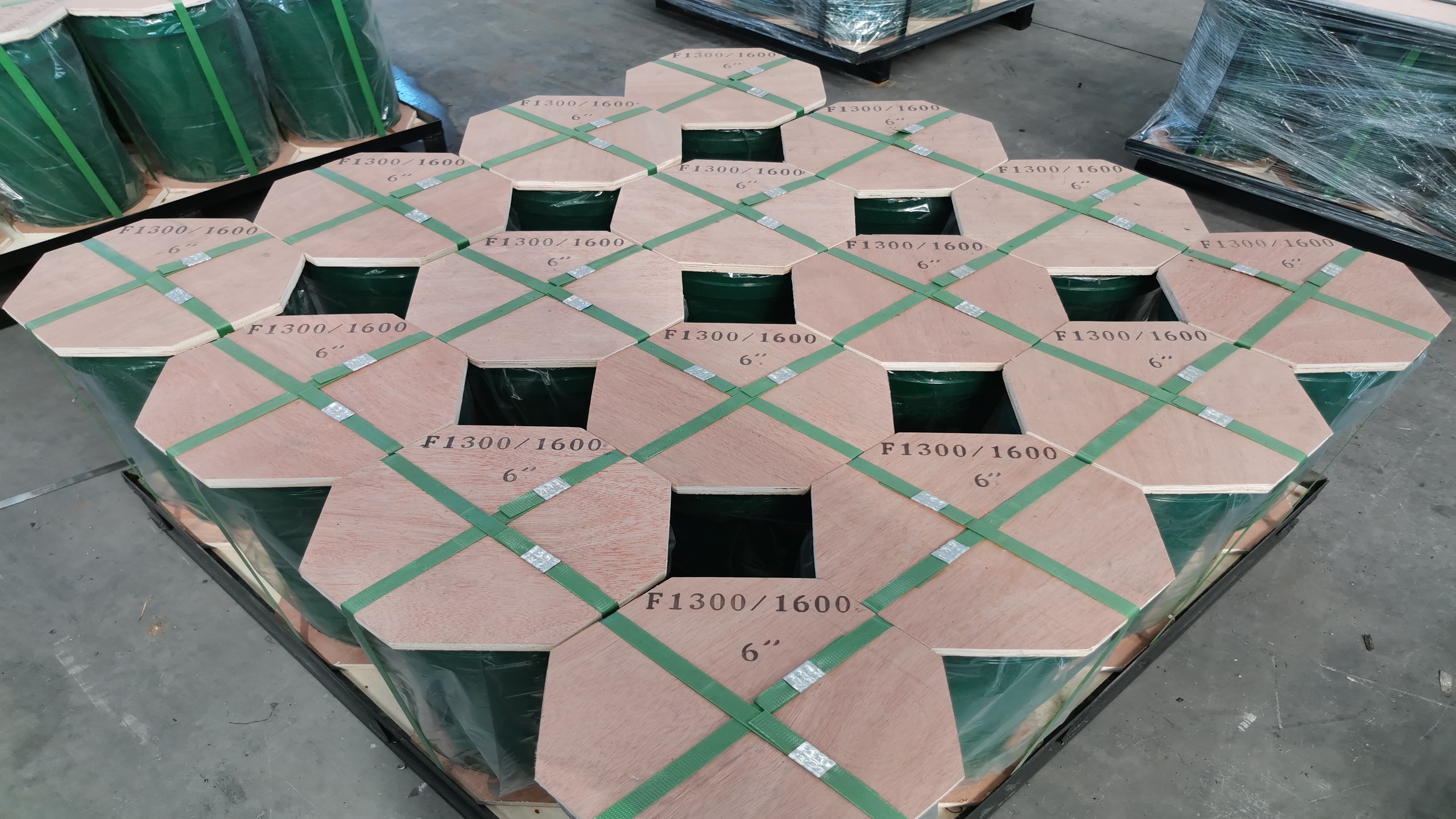

5.Workplace Protection Packaging

A three-level shock and moisture-proof system: Honeycomb EPS mold (cylinder liner) + 3D-printed conformable cover (impeller), reducing transportation loss from 12% to 0.5%.

6.Traceable Global Delivery

A logistics cockpit avoids risk areas. Electronic delivery includes assembly videos and a blockchain-based warranty, achieving a 99.2% acceptance rate.

We are here to answer your questions and support your needs.